A reader has given us an opportunity to see the work of three rare French makers side by side.

| Type | Tin-lined saucepans in hammered finish with cast iron handles fastened with three copper rivets | ||

| French description | Casseroles en cuivre étamés et martelés avec queue de fer munie de trois rivets en cuivre | ||

| Dimensions | 13.5cm diameter by 9.7cm tall (5.3 inches by 3.8 inches) |

13.3cm diameter by 9.5cm tall (5.2 inches by 3.7 inches) |

14cm diameter by 7.8cm tall (5.5 inches by 3.1 inches) |

| Thickness | 2.8 to 3mm at rim, thicker in the base (3.5mm) | 2.3mm at rim, thicker in base (3mm or more) | 2.5mm at rim, thicker in base (3mm) |

| Weight | 1593g (3.5 lbs) |

1530g (3.4 lbs) |

1167g (2.6 lbs) |

| Stampings | “L. JEAN RUE DE VERNEUIL 52”; “LPN”; 19 |

“LEGRY 2. R. MIROMESNIL”; “LPN”; 20 |

“J. JACQUOTOT 128 & 130 R. DE GRENELLE”; “GC” |

| Maker and age estimate | L. Jean; 1879 to 1901, possibly later |

Legry; 1897-late 1920s |

Jacquotot; 1922-1930s |

| Owner | Matt | ||

Paris from the 1880s to the outbreak of the First World War in 1914 — the period we now call the Belle Époque — seems to have been the nexus of an exceptional production of copper cookware. These three saucepans from the collection of reader and antique copper fan Matt give us the opportunity to look at the work of three lesser-known chaudronniers side-by-side.

L. Jean saucepan with matching lid, “LPN 19”

The Jean family opened a chaudronnerie in Paris in the early 1830s. (More precisely, between 1829 and 1833.) The first chaudronnerie Jean was located at 16 rue de Lille in the 7th arrondissement, just across the river from the Louvre. (For that single year there was also Pierre Jean with a chaudronnerie at 18 rue Michel-le-Comte, a little further north in the 3rd, but I did not see that listing again.) In 1840, the shop moved (or perhaps expanded) to 18 rue de Lille; in 1854 the firm moved a second time, a few blocks away to 60 rue Jacob. The final move was in 1860 to 52 rue de Verneuil, still staying in the 7th, where they remained until 1901 when the workshop seems to have closed.

The maker stamp on this saucepan (and its matching lid) reads “L. JEAN RUE DE VERNEUIL, 52,” which may allow us to date it a little more precisely. Up until 1878, the chaudronnerie was listed simply with the family name “Jean,” but in 1879, the listing changed to “Jean (Léon),” and remained so until 1901, the last year in which it was listed. (There was a second Léon Jean at a different address from 1901 to 1907, but he was not a coppersmith but instead a jeweler — I suspect he may have been a son.) I think this is ample evidence that this little pot was made sometime between 1879 and 1901.

Based on the signs of hand craftsmanship I’m seeing, I’d place this little pot towards the early end of that time frame, making it the earliest of these three saucepans (if my estimate is correct).

The first sign I see is the dot, the small divot in the geometric center of the base of the pan (visible in the photo below). This mark was likely left by the point of a compass, which tells me that the coppersmith did not use a metal punch to cut a circle of copper to make the pot. Instead, the smith used the compass to mark a circle and cut the sheet by hand.

The second sign is the gentle irregularity of the surface. This pan has a hammered finish that, while certainly beautiful, is not a regular martelage pattern but looks to me to have been left by the broad hammer that the smith used to shape the pan by hand. I suspect that this pot was not formed with a metal press but instead hammered into shape over a form.

(Please note that I am still learning about these techniques. If you are familiar with historical metalworking I would be very grateful for more information and corrections!)

The matching lid is a great find. Like the pan, it is stamped “LPN 19” for a prior owner. I don’t know what LPN stood for, and the 19 is also a mystery — it’s not the pot’s diameter. I suspect that restaurants or busy chefs kept their own ordering system to match pans with lids, and perhaps this pot was part of a much larger collection that has now been scattered.

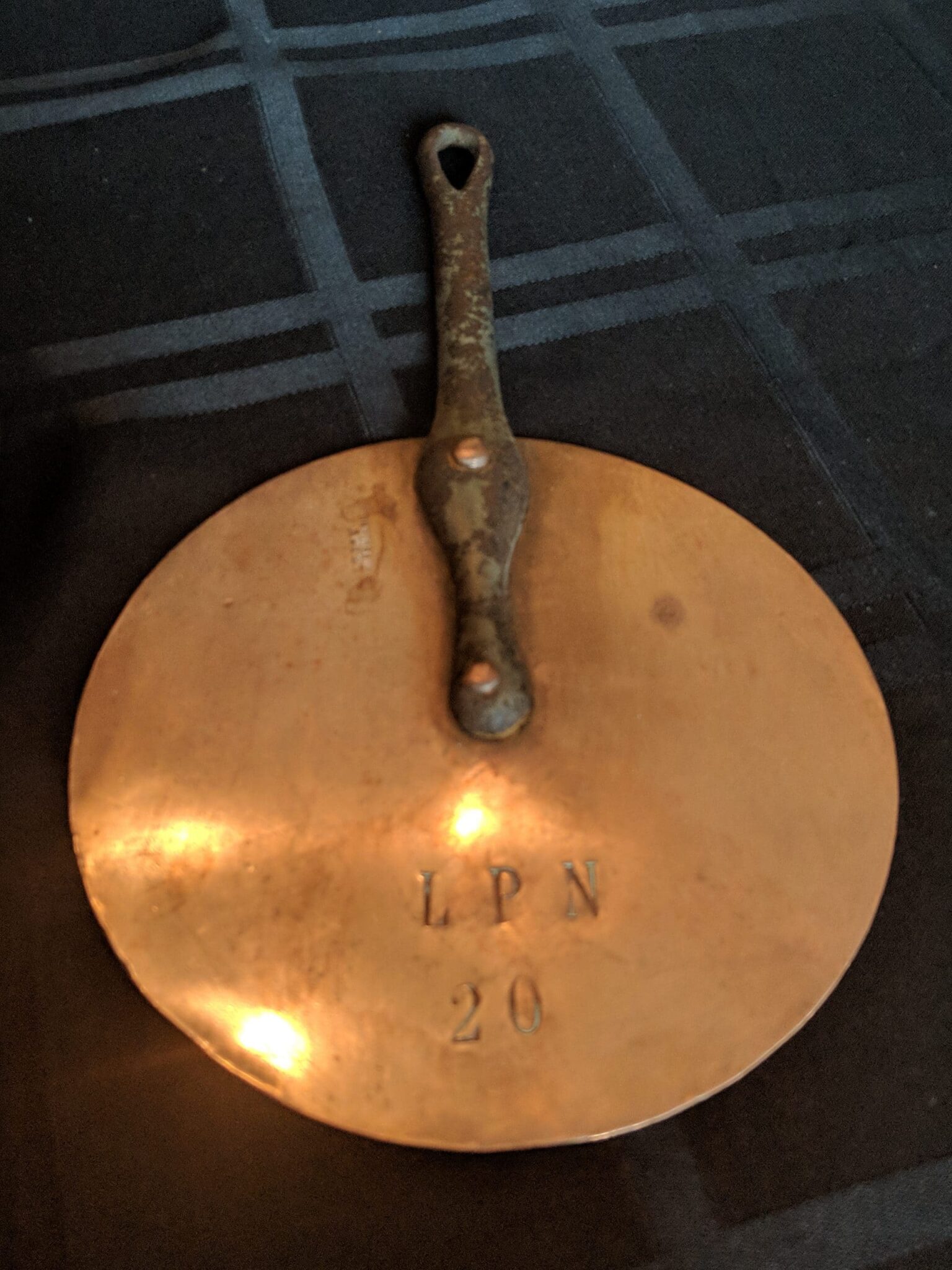

Legry saucepan with matching lid, “LPN 20”

This second saucepan is likely younger than the L. Jean by a few years, but not by much. Legry appeared in Paris in 1897, taking over the shop of Alfred Marie Duval who operated a chaudronnerie at 2 rue Miromesnil until he passed away in 1894. The last listing I can find for the shop is dated 1926; by 1935 it had gone.

This pot has what I believe is an early version of the Legry maker’s mark, a two-line text stamp that reads “LEGRY 2.R.MIROMESNIL.” I have also seen other Legry pans with a round cartouche reading “Legry Cuivrerie Standard” that I suspect is from later production, though I don’t know yet when or why the mark was changed.

Compare the clear hammered finish of this Legry pot to the softer surface of the L. Jean one above.

This Legry pot has true martelage: the purposeful application of hammer strikes in an even distribution over the surface of the pan. Martelage is not merely a decorative addition but also serves to work-harden the copper to help it resist dents during use. I also believe it is a sign that a pan was pressed as extra work-hardening would be redundant for a hand-raised pot. The repeated forceful hammering that shapes a pot also accomplishes that step.

Martelage is a welcome addition to a pressed or spun pan. When I see a pot with martelage, my assumption is that a coppersmith knew the pressed pan was “soft” copper and spent extra time hammering it all over to toughen it. This extra step is a sign of high quality.

These pans have also been hammered around the exterior of the base to produce a beveled edge. I believe this is intended to provide extra work hardening for the copper in this area to help reduce dents around the base, and is another sign of attention to detail.

This pan does not have the dot, suggesting that the smith used a metal punch to cut the copper to form it.

Like the L. Jean pan above, this pan has its original lid, also stamped with the “LPN” owner’s mark. It’s lovely to see these pieces still together after so many years.

Jacquotot saucepan, “GC”

This is the smallest of the three pots, and by my estimation, the youngest as well. This pot has the 128 & 130 rue de Grenelle stamp, suggesting that it was made after 1922 when Jacquotot expanded from its original location at number 130. Jacquotot operated at this location until at least 1938 but records are scanty after that point.

But based on the craftsmanship of this pot, I’d put it towards the early end of that time range, in the 1920s to 1930s. This pot was almost certainly made with the benefit of a metal punch and machine press to form it, but it has beautiful martelage, a hallmark of Jacquotot’s quality.

Note also the beveled base, the product of an extra step of hammering.

This lid is almost certainly older than the pot. The handle is flat wrought iron, not cast; I estimate the lid to be 19th century, possibly the first few decades. But note the Gothic-style stamp: to my eye it looks like “C G.” Could this lid have come from the same owner as the newer Jacquotot pan stamped “G C”?

Thanks again to Matt for sharing these little pots with us. I love seeing how even small pots like these were made with great care and attention to detail to prepare them for a busy kitchen — the lovely martelage, the extra step of beveling the bottom edge. They’re not only beautiful but also designed and intended for work, and here they are a century later, ready to go.

Hi….I’ve always assumed that the faceted external corners on these pots would be evidence of successive rounds of raising a pan from a flat disk on a metal spinning lathe.

I believe it is impossible to raise the pan walls to full vertical in a single step. The reason again is the work hardening of the copper. It would need to be removed from the 1st form, reheated to temper it back to an annealed (soft) condition, then returned to the lathe over a 2nd or 3rd form before the walls could be made vertical.

I’m by no means expert on antique construction methods. But I do have some informed education in metallurgy from my days studying mechanical engineering. I also have several Legry pans, all of which have the faceted external bottom corners. To my eye, these external corners to not appear hammered…..though they certainly have many dings and bumps from their years of service:)

Jeff, thank you so much for your comment! My efforts to reverse-engineer antique copper construction are frustrated by my lack of knowledge and I am really grateful to you for your contribution!

If I understand you correctly, the beveled corners could be a bend or fold rather than an applied planishing, right? If that’s the case, how well would the interior contour of the copper follow the same profile? I ask because my pans with this feature have a sharp 90 degree return that doesn’t follow the shape of the exterior. It also seems like the beveling is in the wrong place on some pans — that is, set too low to be part of the turn. Do you see these same things on yours?