A dentist puts his experience to work to repair a spot of worn tin.

This is a guest post by Dr. Henry Ramirez, DDS.

My wife and I have always admired copper pots, but it wasn’t until we retired that we had the time for its display maintenance.

One of the vintage au gratin pans I purchased on NextDoor showed the copper color through its tinning of about an American quarter coin size so it was a borderline case regarding toxicity.

As a dentist, I had often tin-plated the inside of my gold crowns to increase the bond strength of the cementation. I was able to source the dental electroplating kit on Ebay and a lead-free tinning solution called “421A Liquid Tin” on Amazon. Liquid Tin is a solution of pure tin suspended in a liquid solvent, and while the Liquid Tin itself is not food-safe, the tin it deposits on the surface is pure and non-toxic.

A little research on the web brought up the use of oxalic acid in readying surfaces for plating. This is the active ingredient in my wife’s kitchen cleanser, Bar Keeper’s Friend. I made a paste with water and scrubbed the whole pan then rinsed with hot water. The now-shiny pan was fully dried using a heat gun.

The kit has a grounding clip that is attached to the pan and a small cotton ball squeezed onto the handpiece’s electrode. It uses three size N low-voltage batteries, so there was no fear of electrocution. A good shake of the Liquid Tin bottle and a small pour into the pan. Rubbing the cotton on the exposed copper immediately caused the light gray deposition of tin. The liquid is clear so I didn’t notice that it had retinned other areas inadvertently. Next time I’ll just swab the whole affair!

Here’s a photo of my gratin pan after I completed tin electroplating the entire pan. Really pleased with the result which is smooth as silk.

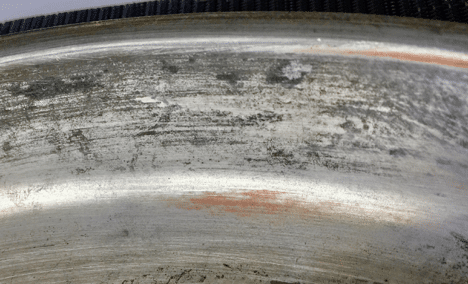

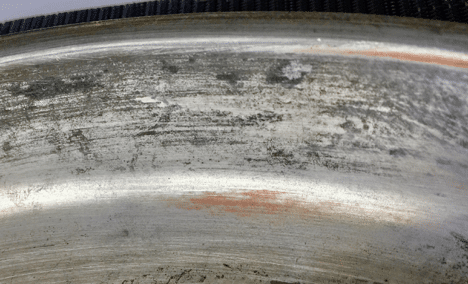

Final before and after photos

VFC says: Thank you, Dr. Ramirez! I know that tin can be electroplated to copper — it’s the best (maybe only) way to get tin to bond to the inside of copper tea kettles, for example. Liquid Tin looks like a small quantity of the same electroplating solution that retinners use. As long as the deposited tin is pure — and Liquid Tin asserts that it is — then I think it’s safe to use on pans. Keep in mind that while the deposited tin layer is enough to coat the surface, it is not nearly as resilient as a hand-wiped tin lining that is several times thicker. But if a pan has minor areas of exposed copper and the rest of the tin is in good shape, this looks like an option to lengthen the lifespan of the lining.

Thanks for the guest post! Has anyone else tried this?

I have an old English pan with a brass plaque attached to the handle stating the interior is electroplated and not to use abrasive cleaners. I have not seen this elsewhere.

I wonder if this apparatus would plate silver with the right solution.

Cake & Pie, as in piece of cake and easy as pie. Get from Amazon some silver electroplating solution (Nushine Silver Plating Solution 3.4 Oz – Permanently Plate Pure Silver onto Worn Silver, Brass, Copper and Bronze (Ecofriendly Formula), and wire up two standard C or D batteries in series. Sit the pan on the negative wire and afix with blue painter’s tape (no adhesive residue). Then use the positive wire with a small cotton ball on the end as your brush after saturating with the silver solution. I just poured 50 ml into my pan and lightly painted with the cotton. Don’t forget to scrub the area with Bar Keeper’s friend first and thoroughly dry with a heat gun or your wife’s hair dryer. There are pic’s of this do-it-yourself rig online if you Google search.

ETA: I should have mentioned that the longer you leave the electrodes attached the better. The grounding wire stays taped to the pan’s bottom and the positive anode wire with the cotton ball stays inside the pan submerged in a shallow reservoir of plating solution. Over hours, the deposition thickness will increase where ever there is still solution. This is ideal for the bottom business end of the pan but trickier to accomplish on the sides.