These very fancy ladies have somehow ended up with the wrong hats.

| Type | Three tin-lined saucepans with iron handles partially coated with copper; three cap-style lids with brass ring handles | ||

| French description | Trois sauteuses étamées avec queues de fer partiellement couvertes en cuivre; trois couvercles emboitant avec anneaux en laiton | ||

| Dimensions | 11cm diameter by 9cm tall (4.3 by 3.5 inches) | 11cm diameter by 9cm tall (4.3 by 3.5 inches) | 12cm diameter by 10cm tall (4.7 by 3.9 inches) |

| Thickness | 2.0mm at rim, thicker in base |

2.2mm at rim, thicker in base |

2.2mm at rim, thicker in base |

| Weight | 1220g (2.7 lbs) | 1256g (2.8 lbs) | 1614g (3.6 lbs) |

| Stampings | All three: LEGRY 2.R.MIROMESNIL | ||

| Coronet; *A* 1 | Coronet; *A* 2 | Coronet; *A* 4 | |

| Maker and age estimate | Legry; 1894 to 1910s? | ||

| Source | lazylou2002 (eBay) | ||

Don’t get me wrong — I love these pans and I love their lids, but I do not believe they all came into this world together. These lids are not the stick-handled style that is usually provided for a saucepan but instead the close-fitting lids from a set of bombes, molds used to make ice cream and other cold desserts. Take a look at Roger’s guest post on his ice cream bombes to get an idea of what these look like. They’re lovely pieces. One is stamped with *A*2, matching one of the pans.

But alas, the lids do not fit. The *A*2 lid slumps loosely atop the *A*4 pot, and the two unstamped lids would need to be jammed quite firmly atop the smaller two pots.

And for pans these lovely, there will be no jamming of lids. Oh my goodness, no.

These three saucepans were made by Legry, part of a set of pans stamped for a royal owner. (I’ll get to the stamps and history a little later.) They are small — the two smaller pans, the twins, are 11cm in diameter, and the larger is just 12cm. But though small in size they are exquisite in their details.

First, they possess one of my favorite qualities in an antique pot: they are bottom-heavy. The best place to have thick copper is in the base of the pan, where it makes contact with both the heat source and the food. This is where the copper does the bulk of its marvelous work to capture and spread heat so that it can reach the food as quickly and evenly as possible. Early pans were hammered by hand from flat sheets of copper and as a consequence often had thinner sidewalls, but even when machine presses could shape the pans, the best French makers (such as Gaillard, Dehillerin, and Legry) ensured that the base retained more thickness than the sides.

I know these pans are bottom-heavy because I can feel it when I pick them up, but even if I did not have them in hand, their weight would tell me. The 11cm saucepans, at 1220-1250g, and the 12cm, at 1600g, are closer in weight to my modern-era 3mm thick 14cm and 16cm saucepans. This is another reminder that antique pans (that is, pre-WWII) with ho-hum rim measurements can pack a punch under the hood, so to speak. (I maintain a big list of reference measurements for this reason and so you can get an idea of the true effective thickness of a prospective purchase.)

Another interesting quality about these pots is that at some point their iron handles were coated with copper.

Much of it has flaked off, but what remains creates a beautiful effect, almost like a lacy overlay.

The areas of the handle not covered by the copper are also beautiful. The iron is rippled, like the wrinkled skin of an elephant. I hope a reader can suggest why this is. My first thought was that this is a consequence of the pour of metal into the mold that shaped the handle. The handle shafts have strong linear graining, which my research suggests indicates that the metal is wrought iron.

This restoration was done by Val Maguire at Southwest Hand Tinning. The pans were in fine physical shape but needed some cleanup and retinning, and she did beautiful work. (In particular, I am grateful for her preservation of the copper on the handles.) The bright clean tin shows the presence of a tiny mark in the very center of the floor of each pan — the dot, left by the compass the smith used to delineate a circle on the sheet of copper. The dot is a sign of 19th century hand-craftsmanship.

The interior rivets are flattened and nearly flush-set. I believe most of them are original. I see very faint numbers on a few of them, which indicates that these pots were assembled with pre-made rivets numbered to indicate their size. Rivet-making machines were a mid-19th century invention.

The center rivet on this pan looks more prominent than the others and I suspect it is a replacement. The outside head of that rivet also looks slightly larger than the others. It was a nice repair job, but the level of finish is not quite the same as the others.

The pans have two beveled planes around the edge of the base. This beveling is added to help harden the copper at these impact points. Despite this, there are a few small dents, but they do not bother me.

And now that we’ve got the pans and their lids covered (heh), we can turn to the stamps and history.

These pans are stamped to the left of the handle for Legry, located at 2 rue Miromesnil in Paris, the former location of the chaudronnerie Duval. Paul Legry took over the business in July 1896; TJFRANCE has compiled a video history of Legry to which I can add very little, but I will summarize the key points.

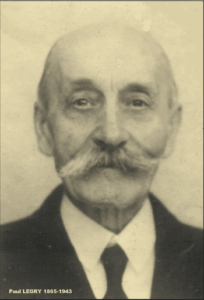

Paul Jean Marie Legry was born in 1865 in Coyolles outside Paris. TJ believes Paul left Coyolles for Paris around 1887 to join his cousin Henri, who had a hardware store at 115 Boulevard Saint-Germain. Paul worked there and at other hardware stores in Paris until his cousin Henri died in February 1896; TJ theorizes that Henri’s death may have given Paul the financial support to buy the Duval business. The last listing I can find for the Legry is dated 1926; by 1935 it had gone. Paul Legry passed away in 1943.

Paul Jean Marie Legry was born in 1865 in Coyolles outside Paris. TJ believes Paul left Coyolles for Paris around 1887 to join his cousin Henri, who had a hardware store at 115 Boulevard Saint-Germain. Paul worked there and at other hardware stores in Paris until his cousin Henri died in February 1896; TJ theorizes that Henri’s death may have given Paul the financial support to buy the Duval business. The last listing I can find for the Legry is dated 1926; by 1935 it had gone. Paul Legry passed away in 1943.

These three pots have the early two-line Legry mark. There is a second stamp that reads “Legry Cuivrerie Standard” but I do not know when that stamp came into use. My best guess is that these pots were made early on — 1896 to the 1910s or so. The other stamps on the pans are quite intriguing. Each pot has a royal coronet, the letter A, and a sequence number (1, 2, or 4).

Sequence numbers are common on sets of cookware in large kitchens, particularly for wealthy or high-ranking owners. And the owner of this pan was high-ranking indeed: my best guess is that this coronet with its strawberry leaves is for a British duke.

But which one? There are three British peerages that begin with the letter A, and here are the gentlemen who held those offices over the time period from 1896 to the 1910s.

John Campbell, 9th Duke of Argyll (more often referred to as the Marquess of Lorne). He was married to Princess Louise (daughter of Queen Victoria) and served as governor-general in Canada from 1878 to 1883; he held this title from 1900 until his death in 1914. (Incidentally, I have a braisière that might have been part of this household.) The Duke of Argyll is a Scottish peerage and the Duke is head of Clan Campbell and Master of the Household of Scotland. John Campbell, 9th Duke of Argyll (more often referred to as the Marquess of Lorne). He was married to Princess Louise (daughter of Queen Victoria) and served as governor-general in Canada from 1878 to 1883; he held this title from 1900 until his death in 1914. (Incidentally, I have a braisière that might have been part of this household.) The Duke of Argyll is a Scottish peerage and the Duke is head of Clan Campbell and Master of the Household of Scotland. |

John Stewart-Murray, 7th Duke of Atholl. This is another Scottish peerage — the Duke of Atholl is the head of mighty Clan Murray. The family’s residence is the beautiful Blair Castle in the Scottish Highlands, which also serves as the base of the Atholl Highlanders, the regimental bodyguards of the Duke and the last legally authorized private army in Europe. John held this title from 1863 until his death in 1917. John Stewart-Murray, 7th Duke of Atholl. This is another Scottish peerage — the Duke of Atholl is the head of mighty Clan Murray. The family’s residence is the beautiful Blair Castle in the Scottish Highlands, which also serves as the base of the Atholl Highlanders, the regimental bodyguards of the Duke and the last legally authorized private army in Europe. John held this title from 1863 until his death in 1917. |

James Hamilton, 2nd Duke of Abercorn. This is an Irish peerage and a relatively young one at that — the Duke of Abercorn was created in 1868. But the family has been a royal peer since the 16th century under James VI of Scotland. James Hamilton, born 1838, became Duke in 1885 and held the title until his death in 1913. He was a particular favorite of the Prince of Wales and was the last to hold the office of Groom of the Stool. James Hamilton, 2nd Duke of Abercorn. This is an Irish peerage and a relatively young one at that — the Duke of Abercorn was created in 1868. But the family has been a royal peer since the 16th century under James VI of Scotland. James Hamilton, born 1838, became Duke in 1885 and held the title until his death in 1913. He was a particular favorite of the Prince of Wales and was the last to hold the office of Groom of the Stool. |

So, reader, what do you think?

A nice story about three elegant ladies!

I hope I won’t be attacked by feminists straight away if I suspect that women’s hats usually meet less practical than optical requirements. Not just at the horse races at Ascot.

In fact, the strange caps remind me a little of berets like the Scots wear. In contrast to the French and Basques Schotish barets have bobbles. If I then interpret the strawberry leaf as a maple leaf, I come to the assumption that this trio belonged to the court kitchen of John Campbell, 9th Duke of Argyll, who also was donor governor of Canada.

More beauties and now you have to find some bombes that need lids.

If you are right and I think you are that the handles have been wrought then the wrinkles will be because the blacksmith began by heating the metal and while it was still part of a long heavy rod banging the end on the anvil. This action spread the end providing the bulk of metal to form into the “T” shape attachment. You could do the same sort of thing with modeling clay or dough to get an idea of how it was worked.

When cleaning up a severely rusted handle I used hydrochloric acid and steel wool, it electro-plated the handle with copper. Could it be that the copper plating on these handles is the result of a similar accident?

Strawberry leaves are mentioned repeatedly in descriptions of British aristocratic crowns. Obviously there must be strawberries whose leaves correspond to these symbols, but not the strawberries that I know and that I found during my research. There may have been other varieties with differently shaped leaves in the past. The heraldic crown of the Portuguese and Spanish infants also bears a great resemblance to the stamped crown, especially the sketched leaves. But I couldn’t find an explanation for these leaves. Possibly the strawberry was a plant and fruit particularly valued by royals, like the lily of the French nobility.

Hi Roger, just wondering where the copper that coated the iron came from in your cleaning method.

Hey Stephen! I sometimes get a faint tinge of pink copper on my iron handles when I clean them with Bistro in the sink. I believe it’s a galvanic reaction — the cleaner in the water creates the salt solution that allows copper ions to plate onto the iron. The layer is quite thin though, and to answer Roger’s question above, the layer of copper on these pots’ handles is much thicker and, I conclude, intentional.

If this is copper plating and not paint it seems to me that, possibly resulting from a custom order, the handles were plated prior to attachment to the pans as this would be the simplest way to do this.

Stephen’s thesis of copper plating is convincing, but I am amazed that this method did not result in a more permanent coating. After all, it should be possible to apply 1-2 mm thick copper layers by galvanizing. A side effect (possibly not only undesirable for me) would be that the handles now heat up more quickly due to the thermal qualities of copper.

However, I think the remaining patina on the handles is very nice.

With a royal client, more permanent, but also more expensive gold plating would have been conceivable. The fire gilding method was already known in ancient Egypt. In modern times, the manufacturer Elkington from Birmingham, England, succeeded in developing a cheaper process for galvanic gold plating of cutlery and dishes in 1840. Apparently the process led to quite durable results, as can be seen from cutlery that has stood the test of time to this day.

Hi Martin, Gold plating for culinary items like plates and utensils that were seen and used by the family and guests is understandable. For pans that were usually only seen and used by the staff a decorative coating of copper would seem to suffice. After decades of handling, scouring, polishing and re-tinning it seems that the thin coating of copper would deteriorate.

Well….I can only say hello to lost friends when I see this trio of Legry pans with their odd covers.

I’m sorry to say I was also a bidder for these when they were sold on the eBay auction in the UK. They confounded me a bit then, I I did not pursue them excessively. I use my culinary copper, and I struggled with how hot these covers with ring pulls would get when the pan is on the stove.

Their initial discovery in the UK might be a meaningful clue as to their 1st owner.

So, they remain beautiful and have certainly been enhanced by their restoration. Use them without the lids and enjoy them just the same:)

Jeff

Upon waking this morning I recall something more about my brief association with these pans when they were being auctioned by the UK seller on eBay.

The seller also had a beautiful, heavy and hammered oval gratin with ring pulls. The gratin had no maker’s Mark, but appeared identical in construction to 2 Legry gratins that were already in my possession. I was fortunate to win the auction for the gratin and I’m very pleased I did. Upon close examination, it does indeed exactly match the construction of the 2 other gratins I have which bear the LEGRY 2 R. MIROMESNIL Mark, it also nests perfectly between its 2 marked relatives. Forming a new “trio” of sorts.

And now perhaps an important clue about this trio of pans with the mis-matched lids and the “crown” mark. While I was trying to establish if the gratin I’d purchased from the seller of these pans might be an unmarked piece from Legry, I asked her if she had obtained the gratin at the same time and in the same place as the trio of Legry pans.

Her answer was yes, but she had not acquired them in the UK. She quickly responded that the were originally purchased at a brocante in France for resale on eBay. That response pleased me, as it lended support to my belief that the gratin I’d purchased was almost certainly from Legry.

So, association of this trio of pans with odd lids with English royalty but found in France?I wonder about that while applauding the research behind the marks on these pans. I also wonder if a similar investigation towards French lineage might yield another curious story.

It causes me to take pause as I have other LEGRY pieces that bear “crown” marks as well as other crest marks from previous, and likely original owners.

Some stories can never end:)

Hello Jeffrey,

We need pictures, there are not enough gratin dishes on the site yet and a graduated set is worthy of a post.

Jeffrey and Roger, I agree wholeheartedly — we need pictures! Jeffrey, I will email you directly. And to my readers, I’ve become aware of an email issue that is keeping some emails from getting to me. If I haven’t responded to a direct email lately, I apologize — it’s possible I haven’t seen it! For the moment the “safest” email for me is [email protected] — it’s a backup email I use as an alternative, and it looks like it’s coming in handy while I’m looking into a possible technical issue with this site’s email. Thank you and again my apologies if I haven’t replied to you!