Yes, you read that right: it’s almost 20 inches across, and that’s just the body of the pan.

| Type | Tin-lined sauté pan in hammered finish with cast iron handle fastened with three copper rivets |

| French description | Sauteuse étamée et martelée avec poignée en fonte munie de trois rivets en cuivre |

| Dimensions | 50cm diameter by 13.5cm tall (19.7 by 5.3 inches) |

| Thickness | 4.0mm at rim |

| Weight | 16900g (37.3 lbs) |

| Stampings | 50 |

| Maker and age estimate | Unknown; 1920s-1930s? |

| Owner | Stephen Whalen |

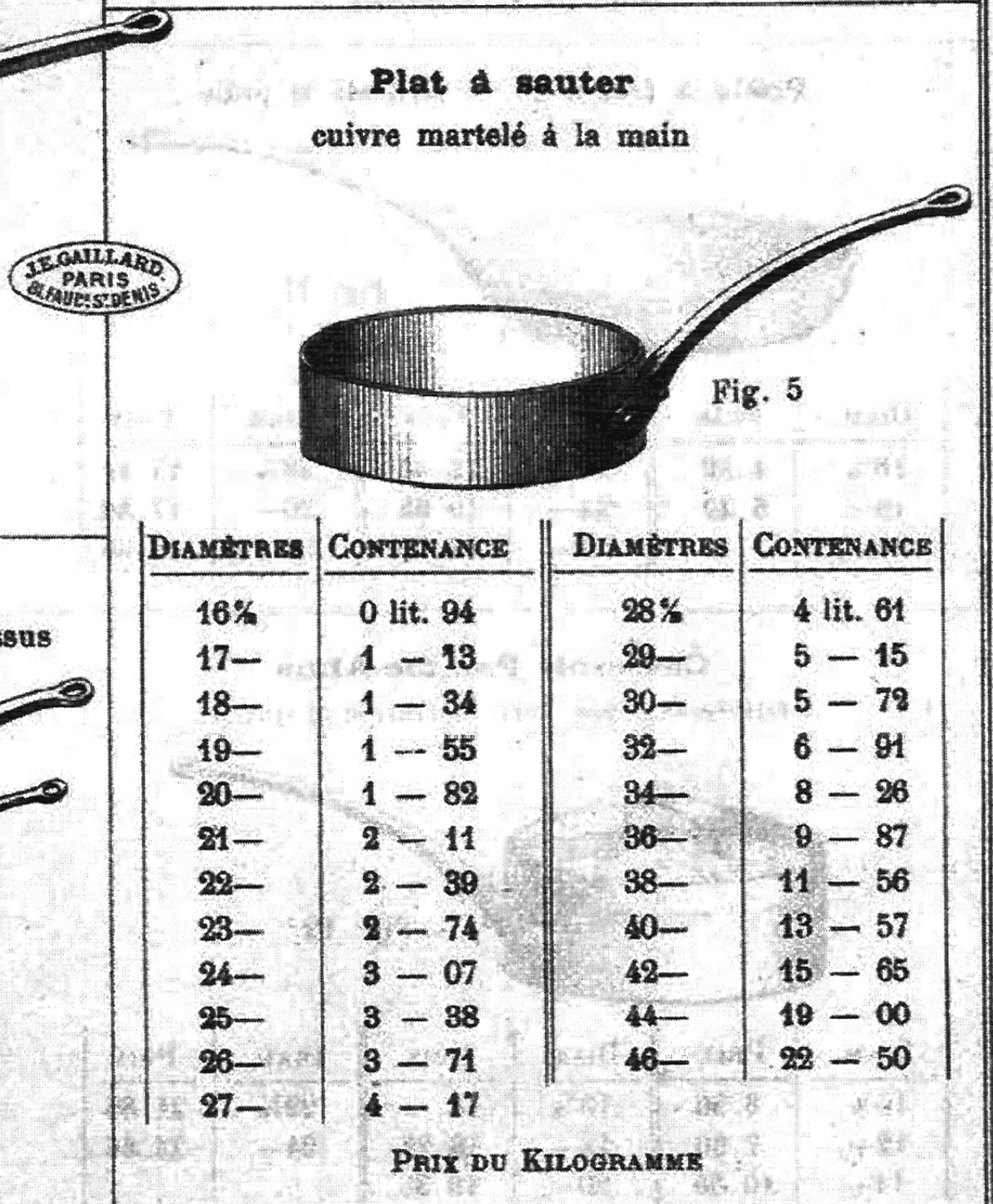

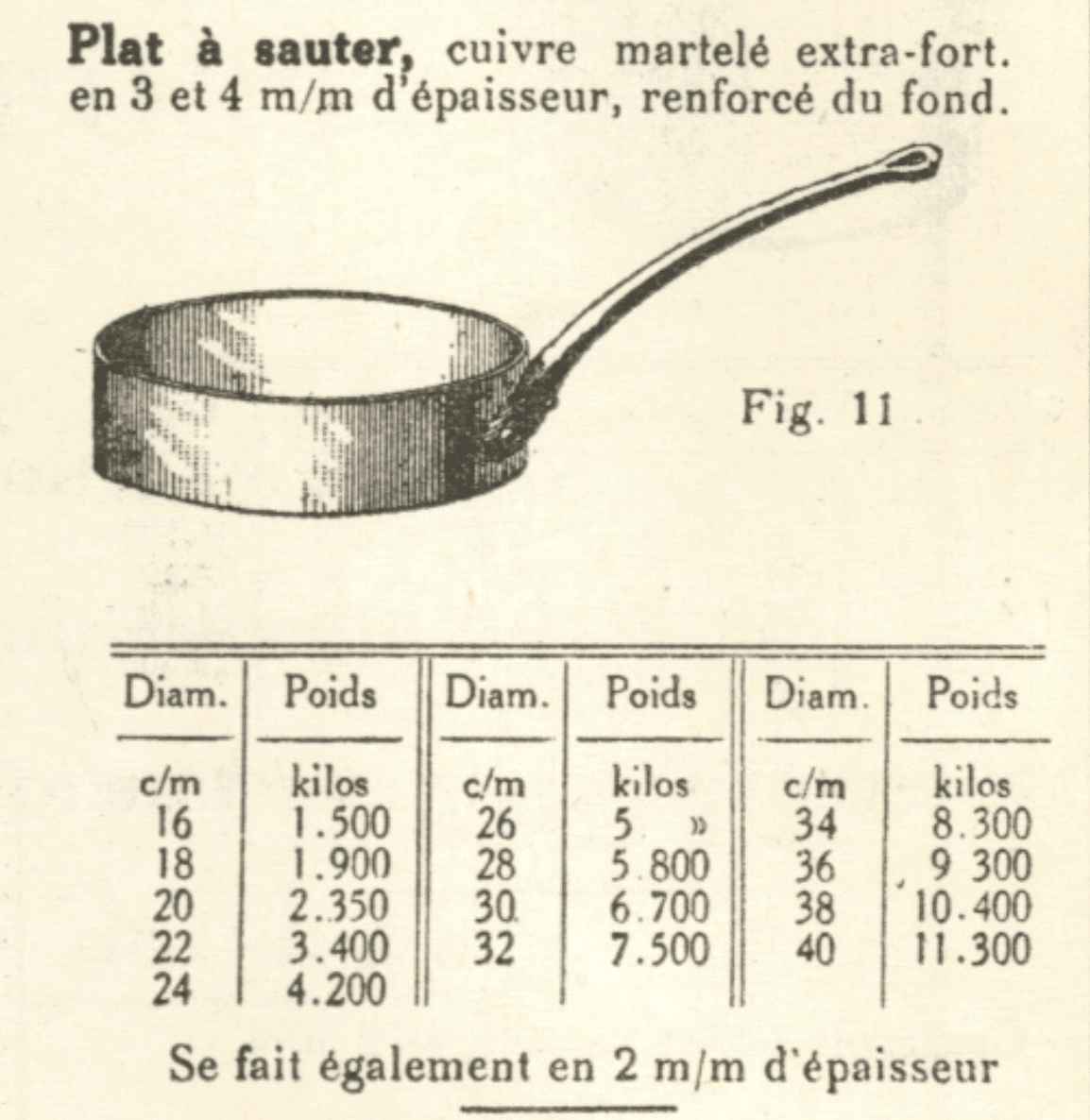

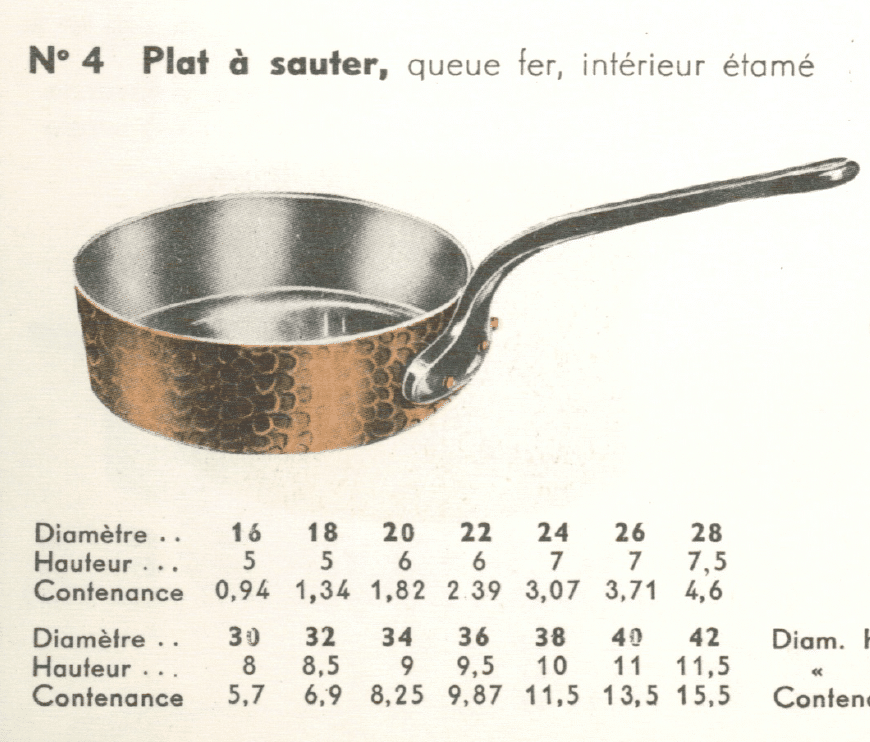

This is a really extraordinary find. Mega-scale restaurant pieces like this were made, and can still be found, but they were rare in their day and I expect only a few survive. As you can see in the three catalogs below — left to right, they are Gaillard (1914), Jacquotot (1925), and Gaillard (1956) — the listed dimensions for sautés topped out in the mid-40s. A piece this big must have been a special order.

It is also 4mm thick. At this scale, I imagine it would have to be thick — the floor of this pan presents a span of unreinforced copper that, if dropped or subjected to some kind of physical shock, would be vulnerable to deformation. The extra-thick 4mm sheet would be necessary to help prevent that. And as you can see below, the floor of the pan is as close to perfectly flat as I can detect. This perfect geometry is really marvelous to see on a piece of this scale.

This piece is beautifully made. Look more closely at the two crisp planes of bevels around the edge of the base: these were applied after the pan was made to help work-harden the copper in this vulnerable area. This extra step is a sign of additional measures taken during manufacture to prepare the piece for service, and I take it as a sign of quality construction.

The handle is cast iron and Stephen measured it at almost 52cm in length (20.5 inches); the baseplate is a full 25cm (9.8 inches) wide.

The exterior rivet heads are small buttons with a few hammer marks on them. The interior rivets are slightly flattened mushroom-heads. I have come to see that the rivets on most restaurant pieces have been re-tightened at some point, if not replaced completely, due to the routine force applied to working pieces in busy kitchens, but I am inclined to think that these are original rivets. The flat impressions on the mushroom heads could be artifacts of the initial fastening — I don’t know enough about compression riveting machines to know for sure.

My observation is that this is an early 20th century piece. The amount of force it would have taken to bend 4mm copper sheet into the body of this piece would have required a very powerful metal press, beyond the capabilities of hand-powered equipment from the 19th century. Steam- and hydraulic-powered presses were developed in the mid-19th century but I do not think they were in use in the copper cookware industry until the very end of the 19th century.

I estimate this piece was made in the 1910s to 1930s based on the combination of machine-assisted elements (metal press, machine-made rivets), hand-finishing (bevels), and the size stamp. There may have been additional stamps to provide more clues to the maker and era but they have been worn away. If my age estimate for this piece is correct, then it could have been produced by one of the larger chaudronneries active at the time: Gaillard, Dehillerin, Legry, or Jacquotot being among the most prominent in Paris, or by several other supplier houses in Villedieu-les-poëles.

I estimate this piece was made in the 1910s to 1930s based on the combination of machine-assisted elements (metal press, machine-made rivets), hand-finishing (bevels), and the size stamp. There may have been additional stamps to provide more clues to the maker and era but they have been worn away. If my age estimate for this piece is correct, then it could have been produced by one of the larger chaudronneries active at the time: Gaillard, Dehillerin, Legry, or Jacquotot being among the most prominent in Paris, or by several other supplier houses in Villedieu-les-poëles.

Whoever made it, it is a stunning piece and in fabulous condition. Says Stephen, “The pan is in excellent shape and has seen little to no use.”

I used fine steel wool on the handle to remove surface rust and then applied a coat of Renaissance wax followed by polishing the copper. I have included a “before” photo of the pan before I cleaned it.

As you can see in the “before” photo above, the pan arrived with a fair amount of tarnish. (That is Stephen’s 46cm Gaillard rondeau in the background, for scale.) But all Stephen needed to do was clean away the tarnish from the exterior to reveal a beautifully shiny and even finish. This piece has been kept in good condition — another miracle for a hefty pan of this scale.

This is truly a spectacular find: monumental 50cm scale, 4mm thickness, perfect geometry, and shiny copper still showing its beautiful hammering. I congratulate Stephen on the acquisition and I am so glad that this marvelous piece has come into his care.

Fantastic piece of history. Are you planning on retinning the interior Stephen?

Hi Chris, For me this will be strictly a showpiece as my modest glass-topped kitchen stove just can’t handle this behemoth.

I can understand that. Very nice piece and congratulations on finding it. I can’t use the majority of my copper cookware where I currently live either. I can’t wait to move into a larger home with a nice big kitchen.

Wow, Stephen! What an incredible pan!! You did an excellent job cleaning it up as well! At nearly 40lbs I can’t imagine that it easy to move around during the cleaning process!.. And on that note this pan makes me think of the phrase, “Don’t mess with the cook!” I bet the cook who handled this pan on a frequent basis was not to be messed with! Haha

Congratulations, what a magnificent addition to your collection!!

Thanks Amy! Yeah, you have to be careful handling these behemoths even when cleaning them. Otherwise it would be very easy to add a dent to them.

For me, it is hard to imagine how this huge sauté pan can be used to make the pieces of meat (food) jump or bounce, even if the cook only tilts the pan on the stove in the process. However, it is possible that this pan was used more like a low roasting pot (rondeau). In any case, a cook had to have much stronger arms than I do. Almost more so, I simultaneously admire and regret the helper who had to clean this pan (multiple times) every day.

In any case, a great find. Congratulations also on the successful refurbishing.

Thank you! I agree about how this pan would have been used. You would have to be a professional weightlifter to jump this pan.

This really is a showpiece, in practical terms it must surely be easier to cook the quality of food this will hold divided into two more manageable size pans. This and the light use plus the care that has been taken to preserve it’s near pristine condition makes me think it was used where diners could watch the chef preparing their food. Some Spanish hotels will have a chef prepare an enormous paella outside as a sort of entertainment. Possibly some chef’s signature dish was similarly prepared and called for such a pan. There is something theatrical about such high quality and freakishly large saute, wonderful and possibly unique. If you are going to hang it up I hope you have sturdy walls!!

Roger, I was thinking along the same line. Seeing its pristine condition made me wonder if it was used as a display piece for a coppersmith or restaurant such as an oversize shoe or boot display was used by shoe stores. Shortly after I purchased this another 50 cm saute pan showed up on ebay from a British seller. A helper handle had been added to the pan at some time which is understandable for something this size. That pan showed much evidence of having been used. These two are the only examples I have seen of a saute pan this size.

Outside of France, the 50 cm (20″) size was definitely offered in series, as early as 1883 in the Duparquet catalog and 1927 in the Gebr. Schwabenland catalog. The considerable time gap between these two catalogs again raises both the question of when and how such large pans were made. I wonder if this sauté pan is indeed of French production, as is assumed. Not only because this size was not offered in any of the French catalogs we have, but also because the handle seems to rise a bit steeper than I know from my French sauté pans. Without direct comparison, however, this is difficult to assess. The shape of the handle of this sauté pan reminds me of some English pans (e.g. my Smith & Matthews).

That’s a really good thought Martin. The pill shape of where the handle meets the pan is also indicative of a lot of old British copper pans like the big bronze handles on Helvetia pans. I’m with you on this pan possibly being British.

Also, some Benham & Sons pans also have pill-shaped handle supports. However, some of these handles are slightly curved and not as straight as the Stephen Whalen pan. To make it a little more complicated: My 33 cm sauté pan also has this slightly rounded handle support (flange), but it is almost certainly of French or Belgian manufacture, as it bears the inscription “Ministere de la Guerre” and was probably made in the early 20th century. Its handle is wonderfully curved, as I have seen in the pans owned by J. de Rothschild (now to be admired in the “Palais VFC”).

I have a saute that has the same handle as Martin’s S & M pan, it doesn’t bear much resemblance to this one. It doesn’t have hammered beveled corners, something which I don’t recall seeing on an English pan. If this was a special order which seems probable then the handle had to be commissioned for it, for regular sizes master handles would be kept from which sand molds for casting were made & these masters would last years. I have noticed that pans can be broadly dated by handle angle & curve. It must have been a conscious decision to modernise the appearance each time a master was replaced because they were unlikely to wear out. The sharp bend away from the body of the pan & then completely straight became the standard form of Mauviel pans from about 1950-75 & the design came from somewhere. The swooping curves of art nouveau period handles which I absolutely love were looking old fashioned by the art deco 1930’s. There is an interesting convergence in design between French & English handle design in the 1920-30’s where the French ones because straighter & the always straight English mostly adopted the French style attachment & rounded cross-section of the grip (Someone forgot to tell Lee & Wilkes). Most handles got to be at a steeper angle perhaps because stove top space was an issue in commercial kitchens.

It looks 100% French to my eye, I am obviously not seeing what others are.

I sent some photos of the pan to the expert T.J. France and, just looking at the photos, his opinion was that the pan was made in Villedieu-les-Poêles in the early 1900s. I bought the pan from a seller in France but was unable to get any history of it from him

Roger, I find your clarification of the variety of English handles very helpful. For me, until now, it was a bit of a muddle that I had a hard time explaining. While many English-made pots/pans could be quickly identified as such, others had handles reminiscent of French handles (with their minor variations depending on the manufacturer). As I mentioned, I have photos of several Benham & Sons pans with handles that bear this resemblance. In fact, I would argue that even a connoisseur would have difficulty determining the country of origin based on these handles alone. One Benham & Sons sauté pan even has a nicely curved handle, which is notoriously rare on UK pans. However, it is made of brass and has a ring-shaped lug. Although Jaeggi & Sons pans were always made of brass, their handles also have much in common with the French models. So far, I have neglected to look to see if there are any English pans with chamfered bottoms. Now I have found some. Some Jaeggi pans have both hammered and beveled bottoms.

To clear up any misunderstanding, I did not claim that the sauté pan featured here is an English pan. I just wasn’t sure if it had actually been made in France and merely noted similarities of the handle (place of bend, angle, straightness) to some English pans. A little later I saw another similarity with the connecting plate of the handle of a sauté pan made in Belgium or France. But in the end, we all know that only from the combination of many construction details is it possible to determine the origin of a pan. Manufacturers from France’s neighboring countries (Belgium, the Netherlands, Switzerland) should not be forgotten! But also the pans from VanNeuss, Pommier, Pianfetti, Pelladda, Regniaud, Vignol, Manzoni etc. show an amazing intravariability of their design features. It is quite complicated.

No academic study done on handles Martin, just what I have observed. The Benham pans seem to be a particularity soft brass and I often see them bent or kinked so please consider as to whether the curved saute might have had a user modification deliberate of otherwise. Jaeggi handles look more like bronze and don’t seem to bend.

In doubt, nameless pans were made by one of the countless nameless craftsmen in Villedieu. You can’t go wrong with this opinion, because you can neither prove nor disprove it.

My thoughts exactly. Making special or unusual items is a market niche where a small workshop might prosper.

Roger, since I do not own any Benham & Sons pans myself and my photo archive on this manufacturer is small, the value of my observations in this regard is limited. In addition, the examples I have stored in my archive show quite different design features. Probably the oldest pan was made with a dovetailed bottom, the cast iron handle has a triangular connecting plate and a keyhole-like suspension lug, and the rim of the saucepan shows a wide tinned rim on the outside. The rivets on the pans I know of show the variety we know from a 2-3 decade time span. There are cast iron handles, which I cannot distinguish from French handles, but also brass or bronze alloy handles with round or oval eyelets. I can’t distinguish the type of alloy on either Benham or Jaeggi due to a slight handicap in my color vision. However, Steven Pearse, a conservator in Cornwall, believes that Jaeggi handles are made of a special alloy otherwise used for casting bells. Jaeggi pans I have seen many and some are in my collection: all had straight handles, sometimes with a round hole, sometimes with a teardrop eye.

I took another close look at the Benham sauté pan with the curved bronze or brass handle. The support plate fits exactly to the curve of the pan. The rivets on the inside are wide and flat, but not completely flush. The outer portion of the rivets is smaller than the space provided in the subplate (recess, cutout). I dare to doubt whether this is indicative of a repair. Rather, I suspect that the manufacturer of the handle provided space for different rivets. The handle is not 100% perfectly curved, there is a small kink at the transition to the round eyelet area. Perhaps it is a custom made according to the wishes of a customer.

Hi Stephen, just wanted to thank you for sharing this information. I have a 20″ Du Parquet Saute Pan that I believe was made in the late 1800’s or early 1900’s. It is Stamped DUPARQUET New York. I would like to sell it. Do you have any advice on selling this?

Thank you in advance,

R H

Hi, Randy,

You may want to reach out to Jim Hamman. He owns original Duparquet molds and is making new pots from them. He also provides retinning services and buys and sells vintage and antique copperware. He bought all my bronze-handled saute and sauce pans when I decided I liked cast iron grips more. And for a little dreaming, I sometimes look at his bespoke sterling silver pans. Contact sites are below.

Best.

Hannah

__________________

duparquet.com

eastcoasttinning.com

Hi Randy, why not post a guest showcase on your 20 inch Duparquet saute? I am sure many of the people here would love to see photos of such a rare pan. As for selling it I can only advise using markets such as Ebay and Craigslist.