The poêlon à sucre is a pan of transformation.

Of course, all cooking is transformation — from cold to hot, from solid to liquid, from disparate ingredients to a fusion of flavors. But there is something special about this piece.

Let’s start with its name, poêlon à sucre. I find that the French word poêlon is difficult to translate directly to English. The root of the word is poêle, which is one of my favorite French cooking terms because it refers to two different things: a skillet, but also an oven. How can a language known for particularity and precision tolerate such ambiguity? I think this is because a language evolves over time, and poêle is a foundational word in the French language that has has a lot of time to evolve.

Let’s start with its name, poêlon à sucre. I find that the French word poêlon is difficult to translate directly to English. The root of the word is poêle, which is one of my favorite French cooking terms because it refers to two different things: a skillet, but also an oven. How can a language known for particularity and precision tolerate such ambiguity? I think this is because a language evolves over time, and poêle is a foundational word in the French language that has has a lot of time to evolve.

In the 14th century, poêle referred to the most basic cooking tool there is: a flat shallow pan with a very long handle that you could hold over an open fire to heat food without burning your hands. (There’s a good example in the photo at right.) But look beyond the physical form of the poêle to its fundamental concept: food on one side, flame on the other. When I think of it this way, the word’s present-day ambiguity of meaning begins to make sense: the concept of poêle can encompass both “skillet” (food above, flame below) as well as “oven” (food on the inside, flame on the outside).

The French suffix -on means “little,” and so logically a poêlon should be a little poêle. But search for the term poêlon at a French-language cookware site (such as the redoubtable Meilleur du chef) and you will see something like the results below. More ambiguity: how can the term poêlon be attached to objects as disparate as a skillet, a small saucepan, and a ceramic escargot baker?

But amidst the confusion arrives a lightning bolt of realization: it’s about the handle, not the pan. Another transformation: a poêlon is a poêle with a stubby little handle, because sometimes you don’t want to hold the food all the way over the fire. Imagine the scene: “Go put this in a poêlon!” yells a harried 14th century French cook to her long-suffering kitchen maid. “And I want you to keep it at the edge of the fire so it won’t burn!”

But amidst the confusion arrives a lightning bolt of realization: it’s about the handle, not the pan. Another transformation: a poêlon is a poêle with a stubby little handle, because sometimes you don’t want to hold the food all the way over the fire. Imagine the scene: “Go put this in a poêlon!” yells a harried 14th century French cook to her long-suffering kitchen maid. “And I want you to keep it at the edge of the fire so it won’t burn!”

And that, of course, is what brings us to the poêlon à sucre, the short-handled poêle dedicated to one of the most exquisite transformations in French cuisine: from sugar to caramel.

Caramel

Cooking pure sugar — that is, boiling away the moisture from sucrose until it caramelizes to a desired color and flavor — is considered one of the trickiest cooking tasks there is. French cuisine designates no fewer than 14 discrete stages in the process:

| Le sirop de sucre, ou le nappé | 212-219.2°F or 100-104°C |

| Le petit filet, ou petit lissé | 222.8°F or 106°C |

| Le grand filet, ou grand lissé | 222.8°F or 106°C |

| Le petit perlé | 226.4°F or 108°C |

| Le grand perlé | 232°F or 111.5°C |

| Le petit souffé | 234.5°F or 112.5°C |

| Le souffé moyen | 239-242.6°F or 115-117°C |

| Le grand souffé | 244.4°F or 118°C |

| Le petit boulé | 246.2-249.8°F or 119-121°C |

| Le grand boulé | 253.4-257°F or 123-125°C |

| Le petit cassé | 258.8-262.4°F or 126-128°C |

| Le grand cassé | 282.2-289.4°F or 139-143°C |

| Le caramel blond | 293-302°F or 145-150°C |

| Le caramel brun | above 302°F or 150°C |

Forgive me for pointing out the obvious here, but there is just one degree Celsius of temperature difference between some of these stages. No wonder caramelizing sugar carries so many cautions: start with a sugar-water mixture to slow the process down; stir it but not too much and only at the right time because if you stir at the wrong time the melted sugar will re-crystallize; don’t burn it but also don’t undercook it or the flavor won’t develop; when you’re ready to stop the process, cool it quickly and thoroughly because superheated sugar retains so much heat that it will burn even when taken off the flame. And for the love of all that is holy, use a candy thermometer so you know exactly what’s going on at all times.

So imagine attempting this delicate transformation in a busy, ill-lit French kitchen in the 19th century. You have no thermometer, no steady flame, and no formal education in food chemistry. Eliza Acton, writing in Modern Cookery in 1845, gives us a sense of what this was like.

The technicalities by which confectioners distinguish the different degrees of sugar-boiling, seem to us calculated rather to puzzle than to assist the reader; and we shall, therefore, confine ourselves to such plain English terms as may suffice, we hope, to explain them.

After having boiled a certain time, the length of which will in a measure depend upon the quality of the sugar as well as the quantity of the water added, it becomes a thin syrup, and it will scarcely form a short thread if a drop be pressed between the thumb and finger and they are then drawn apart; from five to ten minutes more of rapid boiling will bring it to a thick syrup, and when this degree is reached the thread may be drawn from one hand to the other at some length without breaking; but its appearance in dropping from the skimmer will perhaps best denote its being at this point, as it hangs in a sort of string as it falls.

After this the sugar will soon begin to whiten, and to form large bubbles in the pan, when, if it be intended for barley-sugar, or caramel, some lemon-juice or other acid must be added to it, to prevent its graining or becoming sugar again; but if wanted to candy it must be stirred without ceasing until it rises almost to the top of the pan, in one large white mass, when it must be used immediately or ladled out into paper cases or on to dishes, with the utmost expedition, as it passes in an instant almost from this state to one in which it forms a sort of powder, which will render it necessary to add water, to stir it until dissolved, and to reboil it to the proper point. […]

A small quantity should be dropped from time to time into a large basin of cold water by those who are inexperienced in the process; when in falling into this it makes a bubbling noise, and if taken out immediately it snaps clean between the teeth without sticking to them, it must be poured out instantly; if wanted for sugar-spinning, the pan must be plunged as quickly as possible into a vessel of cold water.

And that’s the easy way — starting with sugar diluted in water! The great Antonin Carème, writing in 1842 in Le cuisinier parisien, described the exquisite results produced by M. Laguipière (chef to Napoleon, and to whose memory Carème’s cookbook was passionately dedicated) who had the skill and technique to dry-melt sugar.

Here is his way of proceeding: He melted fine powdered sugar without wetting it, then left it to color little by little on red ashes, which took a quarter of an hour. When it is a beautiful caramel-red shade, you wet it with half a glass of water and put it on a more ardent fire; after a few minutes of boiling, you obtain a very light caramel with a beautiful shade of red, which bears no resemblance to the bitter caramel which is blackened over a high heat and which is commonly called ‘monkey juice’.

Monkey juice! Mon dieu! The soul recoils!

Without a thermometer to tell you where you are in the process, your only hope would be to keep a sharp eye on the pan so you could yank it off the heat at the right moment. And you would need some kind of cooking vessel that would respond quickly to temperature changes as you moved it on and off the heat. Otherwise… monkey juice.

Voilà, the ideal vessel for this delicate act of transformation: the poêlon à sucre.

The pan

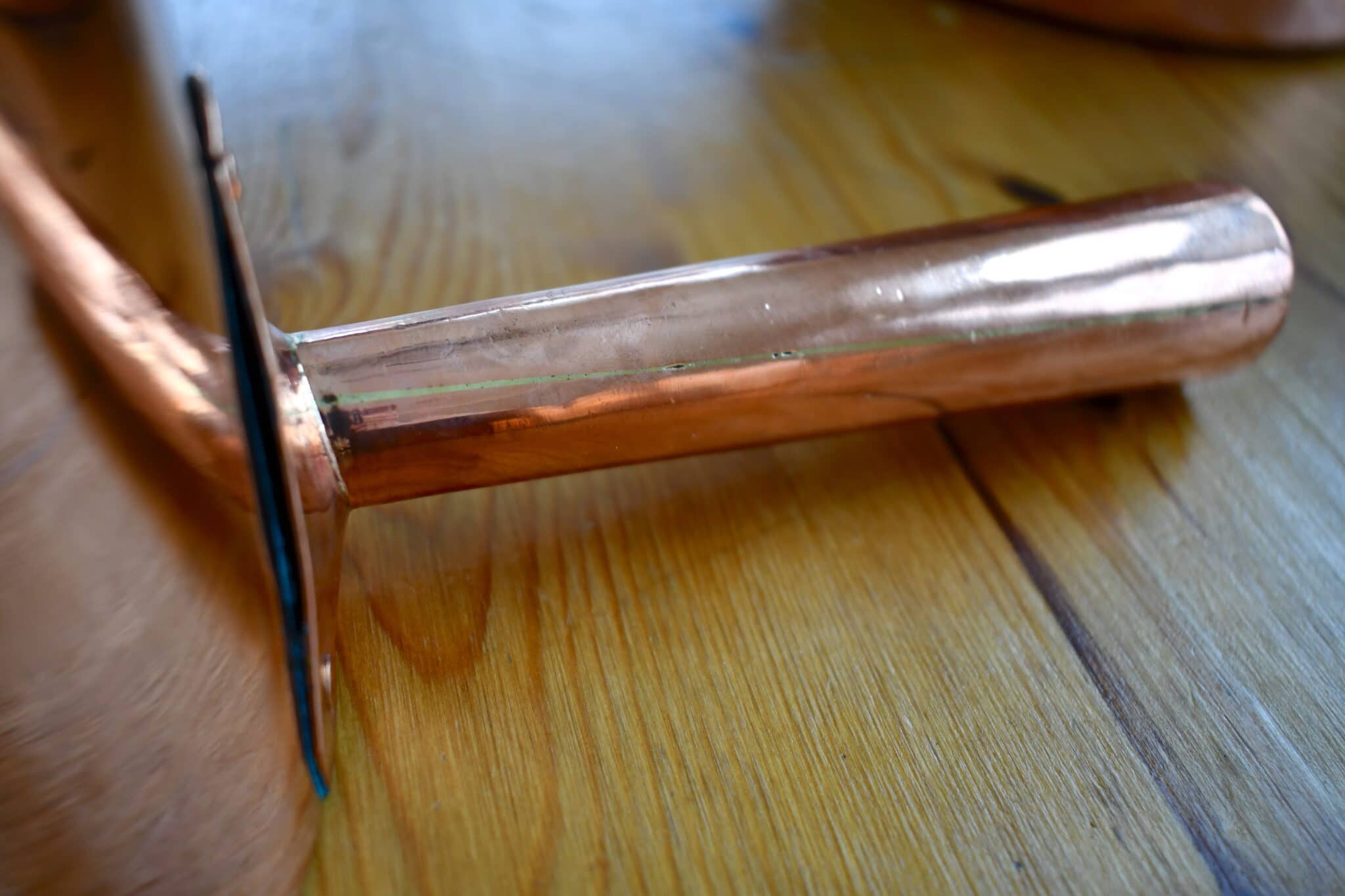

The sugar pan is distinctive: all-copper construction; a flat base; vertical sidewalls; a pouring spout on one side; and a straight tubular handle. Here are a few examples from my collection.

On the left is the largest of the group, stamped with a vertical sans-serif Dehillerin stamp that I suspect is early 20th century, perhaps 1910s-early 1920s. Second from left, in the foreground, is a piece stamped for Jules Gaillard that I believe is 1920s-1930s. Just behind it is a piece stamped for Jacquotot at the 77 Rue Damesme address, which I believe is 1970s-1980s. And finally on the right, tinned, is an unstamped piece that I estimate was made in the mid-20th century.

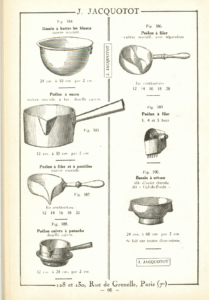

Poêlons à sucre are distinct from poêlons à filer, which are decorating tools with a narrow pouring spout to direct a slender stream of liquid to make lines, as the term à filer implies. At right is a page from Jacquotot’s 1925 catalog showing three variations: a single-spout poêlon à filer et à pastilles, suitable for decorative work as well as to direct a stream of hot sugar into the tiny molds of pastille candies; a poêlon à filer avec séparation, cleverly divided into two chambers to direct twin streams of liquid; and then the stupendous poêlon à filer 3, 4, et 5 becs, a precision instrument with multiple “beaks” for laying down stripes across a vast field of millefeuille.

Poêlons à sucre are distinct from poêlons à filer, which are decorating tools with a narrow pouring spout to direct a slender stream of liquid to make lines, as the term à filer implies. At right is a page from Jacquotot’s 1925 catalog showing three variations: a single-spout poêlon à filer et à pastilles, suitable for decorative work as well as to direct a stream of hot sugar into the tiny molds of pastille candies; a poêlon à filer avec séparation, cleverly divided into two chambers to direct twin streams of liquid; and then the stupendous poêlon à filer 3, 4, et 5 becs, a precision instrument with multiple “beaks” for laying down stripes across a vast field of millefeuille.

An important and distinctive characteristic of the poêlon à filer is that it has a rounded base. This suggests to me how these two poêlons could have worked together: the chef set a sturdy flat-bottom poêlon à sucre on the heat to melt the sugar, and once the sugar was ready, poured the contents into a hand-held poêlon à filer for the decorating work.

The handle

The handle of the sugar pot is a conical tube of copper, and at first blush that seems an inapt choice. The purpose of a sugar pan is to get quite hot indeed — well above the boiling point of water — and a copper handle will conduct that heat right up to the hand holding the pan. Why subject the chef to this, when an iron or steel handle would be more comfortable to hold? (In fact, some modern sugar pans have iron or steel handles instead.)

Well, here’s the thing: I don’t think the heat was meant to reach the hand at all, because the handle of the poêlon à sucre was supposed to have a wooden insert.

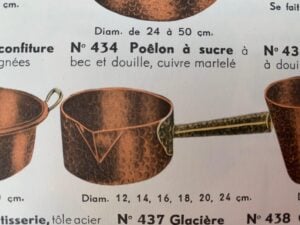

Look again at that 1925 Jacquotot catalog page just above and you will see that the description of the sugar pan reads Poêlon à sucre, cuivre martelé, à bec, douille cuivre. Douille means “socket.” I see the same in Gaiilard’s 1956 catalog: at right is the poêlon à sucre with bec et douille. Interestingly, this colorized image seems to show that the douille and its baseplate were both made of brass, not the all-copper construction we are more accustomed to seeing.

Look again at that 1925 Jacquotot catalog page just above and you will see that the description of the sugar pan reads Poêlon à sucre, cuivre martelé, à bec, douille cuivre. Douille means “socket.” I see the same in Gaiilard’s 1956 catalog: at right is the poêlon à sucre with bec et douille. Interestingly, this colorized image seems to show that the douille and its baseplate were both made of brass, not the all-copper construction we are more accustomed to seeing.

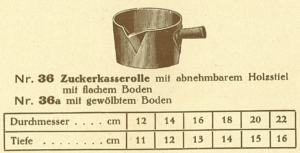

And another piece of evidence suggests that this was not simply a French convention. In its 1927 catalog, the German coppersmith Gebruder Schwabenland offers Zuckerkasserole mit abnehmbaren Holzstiel (“sugar pot with detachable wooden handle”), available mit flachem Boden (“with flat bottom”) or mit gewölbtem Boden (“with curved bottom”). The rendering in the catalog shows a sugar pan with a comically short handle — the detachable wooden handle is obviously not shown.

And another piece of evidence suggests that this was not simply a French convention. In its 1927 catalog, the German coppersmith Gebruder Schwabenland offers Zuckerkasserole mit abnehmbaren Holzstiel (“sugar pot with detachable wooden handle”), available mit flachem Boden (“with flat bottom”) or mit gewölbtem Boden (“with curved bottom”). The rendering in the catalog shows a sugar pan with a comically short handle — the detachable wooden handle is obviously not shown.

I have two poêlons à filer with douilles that retain their wooden handles.

The larger piece has a wooden handle affixed permanently by a small brass pin on the underside of the handle; the smaller piece is more in the German style, with a wooden dowel that simply press-fits within a brass cuff.

Here’s where it gets interesting (to me, at least): the largest (and I suspect oldest) of my poêlons à sucre, the Dehillerin, also has a very small hole drilled towards the end of the handle.

This hole is too small to be a hanging hole. Instead, I think this is a pinhole just like the one I see on my larger poêlon à filer. The edge of the hole is slightly chamfered to allow the head of a pin or screw to settle more flush. I think this hole is a sign that this piece used to have a wooden handle.

None of my other (younger) poêlons à sucre have a pinhole. I took a spin around Etsy and eBay for sugar pans and I noticed something similar: the older pieces — the antiques — are more likely to have pinholes, while the younger pieces (for example, those with MADE IN FRANCE or VILLEDIEU FRANCE stamps that represent modern-era work) don’t seem to have them at all. I am coming to suspect that the poêlon à sucre was intended to have a wooden insert, but at some point the wooden handle was no longer provided with the purchase, and we have since grown accustomed to the empty douille. My first thought would be WWII as that inflection point.

Of course my sample size is quite small — one piece! — and so this is just my conjecture. I’d welcome input from readers who have sugar pans to add more data points. Does your piece have a wooden handle or the pinhole to fasten one?

The joinery

Virtually all of the sugar pans I have seen are made completely of copper: copper baseplate, copper handle, copper body. (My own poêlon à filer with its brass baseplate is the one exception I’ve seen but I remind myself that the 1956 Gaillard catalog shows a brass douille.) Consider for a moment what this implies: the entire thing could be made by hand from thin sheet copper. The pan could be hand-raised, pressed with hand-cranked machinery, or lathe-spun; the baseplate could be clipped with hand shears and the handle made from sheet rolled into a tube and sealed along the seam. This is workshop labor that does not necessitate machine power to accomplish, which means we have an opportunity to observe human ingenuity in action. Just how was the handle put onto this pan?

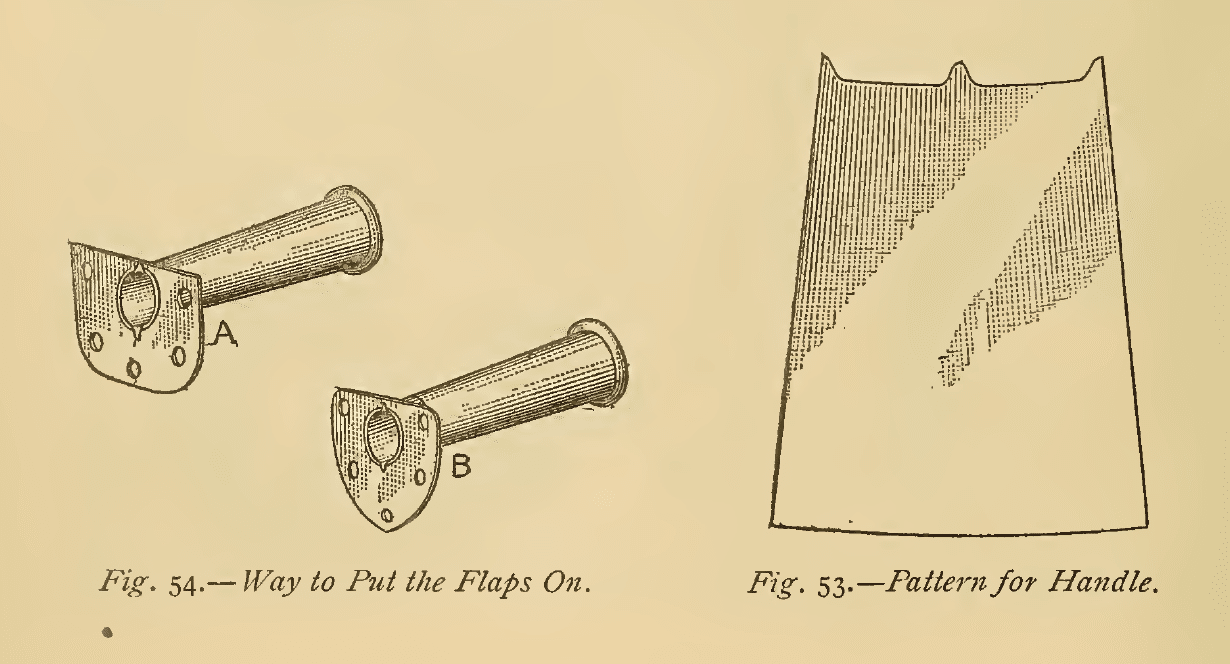

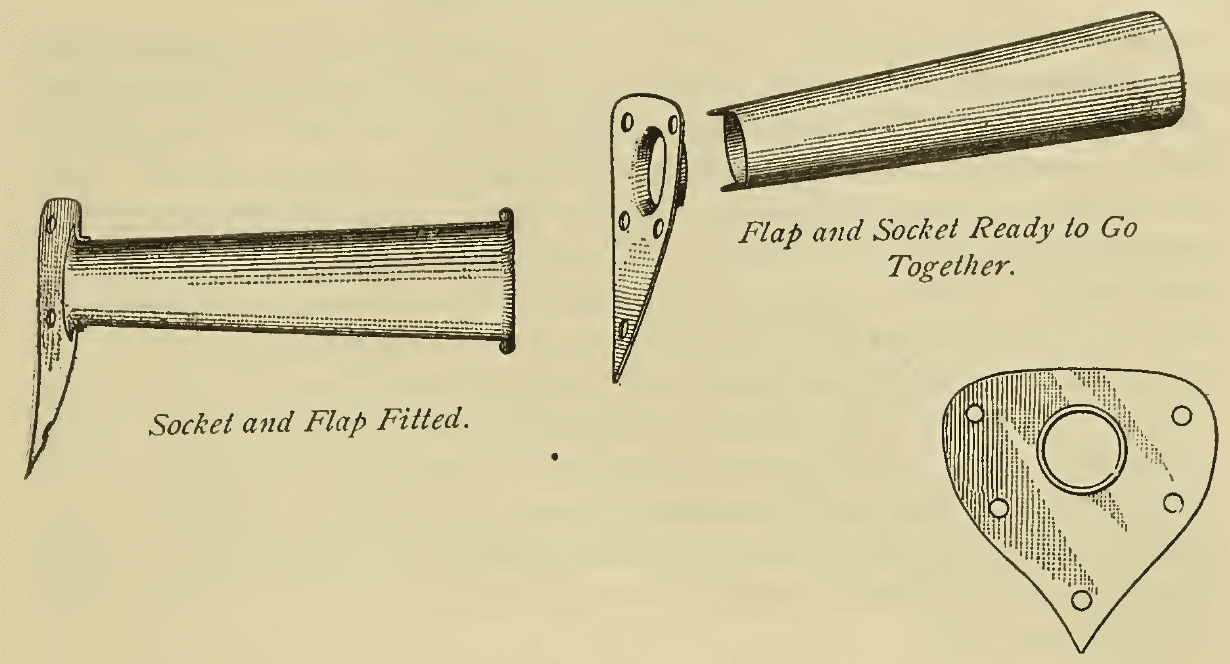

John Fuller in his 1893 book Art of Coppersmithing describes how this was done in the English style, which he calls a “socket handle.” The attachment end of the handle tube — the socket — was cut with “V-pieces” and the baseplate — the “flap” — was fitted over the end. The V-pieces were bent outward to hold the socket in the flap while it was attached to the pan. Finally, the join was filled with solder to fix the handle firmly in place.

Two of my French pieces look to have been attached in the same way. The seam between the handle and the baseplate is quite clean with just a bit of yellow brazing.

But these other two of mine look different. The Dehillerin on the left (estimated 1910s-1920s) has a pronounced raised area around the join and no braze or solder is apparent to my eye. I suspect that the entire end of the handle was bent outward, so that the baseplate serves as a proper collar clamping the handle to the body. If I am correct, this may explain why there is no filler metal there — it wasn’t necessary. The Jacquotot on the right is a much later piece (likely post 1970s) but the baseplate also looks like a collar to my eye.

The seam on the underside of these handles is brazed — you can see the telltale yellow seam of brass. Left to right in the photo below are the Dehillerin, the Jules Gaillard, and the unstamped one.

The Jacquotot, by comparison, is welded. The join is denoted by a slightly darker seam of copper metal running along the underside.

Is the brazing on my unstamped pan an indication that it is older than the welded 1970s-era Jacquotot? I am tempted to think so, but I am not ready to say for sure. Brazing is a convenient method to join copper and continued well into the 20th century to assemble pieces that couldn’t be pressed or spun (such as turbotières, daubières, and deep stockpots); however, welding is faster and produces a stronger join, and Mauviel transitioned decades ago to welding pieces that were traditionally brazed with cramp seams (i.e., dovetails).

For this reason, I think that brazing on a small piece like this is not a definitive indication that it is an antique (that is, pre-WWII) piece. In my opinion, brazing could have persisted beyond WWII as an economical technique for small workshops.

To tin, or not to tin?

We have all learned that copper pans must be lined: cooking food produces acids that, with heat and prolonged contact, react with bare copper to produce toxic chemical compounds. But sugar pans, jam pans, and mixing bowls are an exception, as they are conventionally used for specific cooking tasks that don’t produce the acids in question. The caramelization of sugar — that is, the combustion of sucrose — is a chemically complex process, but none of its products react with copper. It is therefore not necessary to tin a sugar pot that is used as intended for confectionary work.

But that said, could you tin it? Of course. Tinning would turn a sugar pan into a saucepan with a pouring spout. But it’s worth considering what kind of saucepan this would make. In my experience, sugar pans are usually 2mm or less by design; Mauviel termed pans under 2mm thick “table service grade” because they were not thick enough to withstand the rigors of stovetop use. (Indeed, my antique sugar pans are all dented across the floor of the pan.) The thin copper would also heat up and cool down quite quickly (as intended for sugar confectionary), but this thermal responsiveness would be muted if you were to use it as a conventional saucepan — that is, filling it with liquid. (A water-filled pan heats and cools according to the heat capacity of the water and is not appreciably affected by the thickness of the copper sidewalls.)

My advice to you — and my opinion — is that tinning a 1-2mm thick sugar pan would increase its general utility but would not necessarily give you a workhorse saucepan. It should be perfectly competent at liquid cooking — heating water, making fluid sauces, and so forth. But I’d offer a few caveats: Be careful with cooking thick sauces and rice dishes that are prone to scorching. Be mindful of dings and dents, particularly for a sub-2mm piece. And finally, the traditional “socket handle” on an early piece is likely not as resilient as a riveted iron or brass handle, so I’d be hesitant to load it up with heavy contents.

Update: An important consideration in choosing whether or not to tin a sugar pan is that it would be rendered less suitable for confectionary work due to tin’s softening at high temperature. In other words, once you tin a sugar pan, there may be no going back to using it for sugar confectionary — the tin will soften and melt and spoil the caramel. (Thanks to reader Dietmar for trying this out and reporting his results.)

Conclusion

Readers, I hope this has been an interesting post for you. I certainly learned a lot as I researched this type of cooking — I never paid much attention to sugar pans before. If you like this, I can try more “Get to know…” for other specific pan types.

Also, I’m interested in your experiences cooking with them — whether for confectionary or as a general-purpose saucepan.

Dear VFC, thank you for this interesting insight into the world of sugar pans. I have actually never dared to use my tinned copper pans for making caramel. But you are right, of course: the temperatures necessary for caramelization should not affect the tin coating.

However, we have a pretty “robust” way of making caramel in our family:

We just use a regular Falk copper sauciere with stainless steel lining and let the sugar boil down with very little water (no stirring at all, at most swirling the pan gently) over maximum heat until it’s the color we want. The browning stops immediately when the pan is moved to a cool spot on the ceramic hob. When stirring, too much sugar would actually crystallize on the cold stirring spoon, accordingly the constant maximum heat prevents the sugar from crystallizing on the otherwise too cool edge of the pan (we use an electric Ceran cooktop, on gas this may not be such a big problem).

Using this technique, which admittedly has no regard for old French cookbooks, even my 14-year-old son has a lovely, usable caramel in the pan in 5 minutes (which he regularly needs to make fantastic flans and other caramel-containing treats). The important thing is: don’t think too much, just do it!

And by the way, if you stir the appropriate amount of fresh fruit into the finished caramel and cook for another 15 minutes, you get an exceptionally delicious jam.

But it was about sugar pans made of copper – sorry for the digression….

Dietmar, this is marvelous. Thank you!

So interesting especially your caveats for use. I have a Gaillard that looks similar to yours. It’s saved for the times I need to use it as intended for sugar.

I’d love to see a post on jam pans; maybe both the French and English styles.

Sus, just such a post may be in the works…!

My sugar pan came with a wooden handle held in place by a screw, I’m sure it is not the original, looks like it was intended for a garden trowel. I varnished the handle and replaced the rusty screw with a brass one. The interior of the pan was pitted so I did tin it to make it usable as a milk pan. It has a very worn crown mark so probably came from a noble house. The handle attachment is heart shaped. Possibly English?

Roger, I expect the wooden handle inserts were intended to be replaceable.

Dear VFC, earlier I did a rather interesting experiment: after thinking about whether sugar pans could be tinned, I tried making caramel in one of my less valuable tinned copper saucepans (16 cm, from the 1970s, 2.5 mm copper thickness). This time not “full throttle”, as I am used to from my copper pans with stainless steel coating, but nice and slow, with medium heat.

And the result of this: when the caramel was light brown (~150°C in the sugar), the tin actually began to melt! Apparently it gets quite hot under the bubbling sugar, probably the thermal conductivity of the melted sugar is not high enough to dissipate the temperature from the metal. Incidentally, during all the action, the dark discoloration that forms in tinned copper pans with prolonged use also came off and “decorated” the caramel with small flakes.

The test caramel, unfortunately, was for the trash can. Fortunately, copper pans with a melted tin layer can’t worry me too much thanks to VFC. The casserole will continue to do its job in sauce preparation.

What do we learn from this: the French chefs of earlier centuries knew very well why they used special, untinned sugar pans, which, moreover, were not used for anything else.

Dietmar, thank you for sharing the results of this experiment! I will add an important note to the post: if you choose to tin your sugar pan, it will be less suitable for high-temperature confectionary work.

Molten sugar can boil well above the melting temperature of tin and strip tin from copper. Worse still, “sticky” sugar will adhere to tin when as it cools. I have done this, terrible mess.

Acids do not react with pure copper, however oxygen does and the oxides of copper formed will react with acids. Salts in solution increase the rate of dissolution of copper oxides by increasing the ionic strength of water. The human body can excrete copper in urine, to compare, our bodies cannot excrete iron.

When you make jam in a jam pot with visible copper oxidation, copper will go into the jam unless you remove the oxidation first. Not so much with pure sugar. However, if you add water to moisten your sugar, yes, you will remove oxides of copper. Same goes with whipping egg whites in a copper bowl.

Remember, your body excretes copper in urine. So, it’s not much of a big deal. I am not advocating eating copper, but at the milligram amounts you are getting your body is likely excreting it faster than you are eating it. This is, hey I am a chemist and this is how I see my risk.

I am a pâtissier and I have 14 copper sugar pots😂. I love them! I have one set if 5 vintage hammered Matfer, only they have the pinholes.

You shouldn’t tin a sugar pot because somehow the copper stops caramel from re-crystallize.

And you can cook caramel in tinned copper, I so that often. The caramel would be totally black and smoke like crazy before it reaches the melting temperature of tin. 😉