Readers, you’re in for a treat.

Monsieur Jean Boisserie, proprietor of Atelier Boisserie in Corrèze, Nouvelle-Acquitiaine, France, is a master coppersmith who works completely by hand — he hand-raises copper from flat sheet, outsourcing only handles, rivets, and other minor pieces of hardware that need to be cast. He makes artistic and culinary copper and also repairs and retins cookware in his workshop at 40 Rue Marc Chadourne in the village of Le Pontour. He works by himself with no advertising, no website, and no online store.

Monsieur Jean Boisserie, proprietor of Atelier Boisserie in Corrèze, Nouvelle-Acquitiaine, France, is a master coppersmith who works completely by hand — he hand-raises copper from flat sheet, outsourcing only handles, rivets, and other minor pieces of hardware that need to be cast. He makes artistic and culinary copper and also repairs and retins cookware in his workshop at 40 Rue Marc Chadourne in the village of Le Pontour. He works by himself with no advertising, no website, and no online store.

Reader and copper seller Greg M. conducted an interview of M. Boisserie to celebrate his work and bring him to the attention of more copper aficionados.

M. Boisserie, how did you learn this craft?

M Boisserie responds: I wasn’t destined to do this job. I was destined to work in industry. I began training in a technical school where I earned three professional aptitude certificates (industrial teaching certificates), a level of studies high enough to achieve an excellent career in industry. But, as a man falls in love with a woman, I fell in love with copper (women as well, but that was later)… and I decided to do this job.

So, in order to train in the domain of copper, I went to an artisan who was already one of the best in France. He was not a coppersmith but a master copper boilermaker (cauldrons, large vessels). I entered his company and stayed there for about 10 years with two short breaks because I tried to go work in some other companies, still in France. But the artisans were not at the same level of qualification, so I had fallen in the right place right from the beginning. At the end of those 10 years, I established my own company and I have always done this job!

When did you open this shop?

I opened this business in 1966. It’s my passion for the profession which made me act because it was a period where boilermakers and coppersmiths were disappearing. The commercialization was not easy, they worked with resellers… so, I completely changed my objective and decided to work with individuals. For this purpose, I did demonstrations. I never proposed to go to the clients, but during public demonstrations I showed my profession, and I explained the process which attracted many people to my workshop. If I had worked mechanically, of course, I could have earned a lot of money, but that wasn’t the goal. What truly inspired me was working with my hands. At the beginning I hired two workers, and I realized that, if I had personnel, I could not completely commit myself to the profession, so I decided to work alone.

I opened this business in 1966. It’s my passion for the profession which made me act because it was a period where boilermakers and coppersmiths were disappearing. The commercialization was not easy, they worked with resellers… so, I completely changed my objective and decided to work with individuals. For this purpose, I did demonstrations. I never proposed to go to the clients, but during public demonstrations I showed my profession, and I explained the process which attracted many people to my workshop. If I had worked mechanically, of course, I could have earned a lot of money, but that wasn’t the goal. What truly inspired me was working with my hands. At the beginning I hired two workers, and I realized that, if I had personnel, I could not completely commit myself to the profession, so I decided to work alone.

What other metalworking experience have you had?

My initial training was working with sheet metal. It was sheets in steel, stainless steel, aluminum then later copper, bronze and silver and any other metals that are available in sheets. I never stopped perfecting myself. I am curious by nature, and I always try to learn something new. That’s why I can not stop doing this job — there are always new things to learn. It was my life. I had great fortune thanks to marvelous clients who kept asking for unexpected things. I NEVER did any advertising! Never did I have the need to go sell my products outside of my own company because clients came to me. Advertising was done by word of mouth and only that way. I owe my clients a lot.

What thicknesses of copper do you work with?

Copper is easy to find, with a lot of money currently of course. There are numerous copper suppliers in France or abroad. The last order was from Italy, for example. Germany, France… there’s no problem finding it. Concerning the thickness, in the artistic field, it’s fairly thin, between 0.8 and 1mm. In the culinary realm, much thicker copper is needed, 2mm or 3mm, because it must transmit the heat. For cooking it’s very important. It’s a wonderful material. Copper for great cooks is THE material to use! Unfortunately, more and more are being replaced by stainless steel, but the output is NOT AT ALL the same quality. The inconvenience of copper is that it demands more upkeep. And as labor costs are high, one tries to go cheaper… and faster.

Concerning the nuances of the materials, I work with different materials responding to different requests because I make culinary pieces as well as artistic, even though the latter has become less appreciated in France, but I cater to the request. I create objects such as signs, weathervanes, steeple décor, roof finials… whatever someone asks. You can see behind me a cluster of grapes. This is a sign for a wine producer.

How do you shape your pieces? Do you spin, press, or hand-raise them, or some combination?

Generally, I produce the entire piece myself. But, in the case of a casserole I did it in the beginning, but it became too expensive, so I sought out suppliers for certain parts [the handles and rivets].

What handles do you use for the culinary copper?

When I began working, brass handles were all the rage. As it was yellow, people thought it was prettier… but very quickly we realized it was too strong a heat conductor and we returned to a material called malleable [cast] iron. It’s melted, it’s very strong, we can hammer it, it’s durable, it oxidizes less, and it shows better. But above all, I wanted to do it the older, traditional way. You know, our elders knew good methods. They had imagination; they didn’t produce things in any old manner… they ALWAYS had a reason, perhaps hidden, for one use or another.

What other objects do you make?

I make very diverse objects. It could mean small, even minuscule objects. I even build stills, which means I build objects of many sizes. I do goldsmithing (jewelry, etc.), I work with precious metals as well, so they are of a small size and for the distillery industry they are very large. Now, because I am older, I mustn’t make objects that are too big since they are, obviously, more difficult, heavier… but I like just as much to make an industrial object as an artistic one.

For me, it’s always a challenge to take a sheet of metal, to face it straight on and to fight in order to reach a desired result. As much as people think we have a gift to so something, that it’s very easy, it’s not true! Each time that we make an object, we find ourselves up against a wall and we must use all our knowledge to achieve a good result. The material is rebellious, and we must master it, so it’s always a challenge to do it. It’s very interesting.

Do you cook with copper? If so, what do you have in your batterie de cuisine?

I do not cook myself; I leave the cooking to my wife, who is a very good cook when she wants. Obviously, she cooks in copper, not for everything (there are other materials than just copper), but the essentials are the sauté pan, casseroles (pots and pans), the cocotte à poulet (chicken crock or Dutch oven) … The cocotte à poulet is a very interesting piece because we can cook a chicken, we can make a ragoût, simmer something, it’s like a cauldron or kettle… they are oval to be adapted to the chicken’s shape, but in a kitchen it’s VERY IMPORTANT to have sauté pans, especially, AND the cocotte. The rest, well, it varies but we have all of these, and we use them all, especially when we have guests!

After the conclusion of the interview, M. Boisserie graciously allowed Greg to take more photos around the workshop and store.

Below are two views of an assortment of pieces for sale: a skillet, two sauté pans, a poissonière, an unlined jam pan, and an oval cocotte à poulet.

This is a 26cm sauté pan at 3mm thickness.

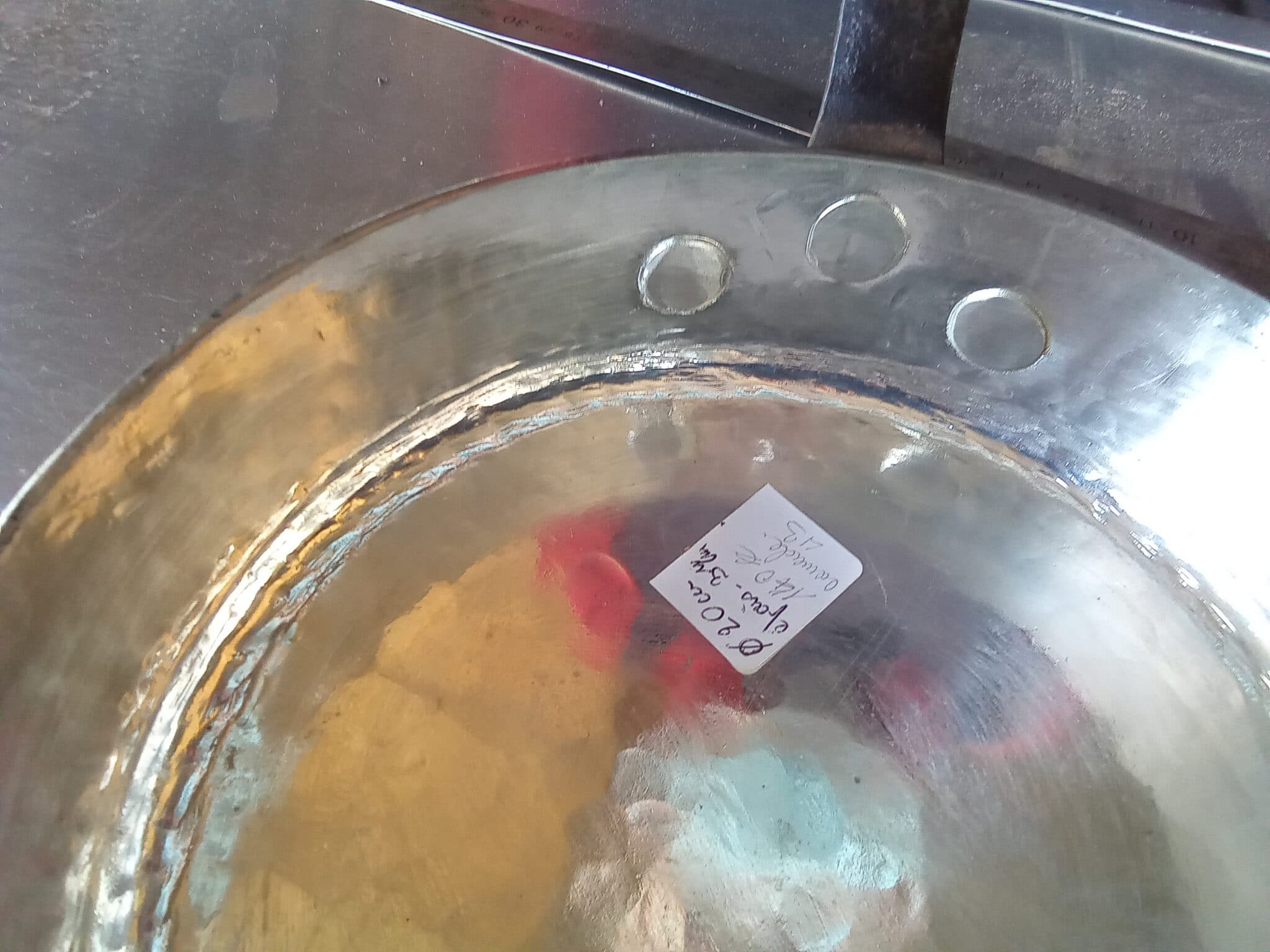

The photos below of a 20cm sauté show the distinctive appearance of hand-raised copper. This is the difference I observe between exterior surface martelage and hammering for shaping: whereas martelage is applied on the exterior surfaces after the piece has been machine-shaped, hand-raising produces uniform hammer marks across the interior as well as exterior of the piece.

Note the bevels laid down around the edge of the base. This is exquisite.

Below is M. Boisserie at work retinning a pan. He has coated the interior of the stripped pan with a flux that has tin granules mixed into it. Then he applies flame from a torch. As the pan heats up, the tin melts and adheres to the pan walls. He then wipes it to cover any skips and the excess goes into the next pan to be tinned.

VFC says: Greg, I cannot thank you enough for bringing us inside Atelier Boisserie to meet M. Boisserie and appreciate his gorgeous work. He is a world-class coppersmith — the meilleur ouvrier de France designation on his business card (“best workman in France”) is a formal designation accorded annually to a small number of individuals, an honor he earned in 1972.

A bit of research uncovered that M. Boisserie is also a member of the European Music Archeology Project (EMAP) that researches and re-creates ancient musical instruments for performances in the present day. Among other instruments he has contributed, M. Boisseries is the maker of the Tintignac Carnyx — a reconstruction of an ancient Celtic horn with the head of a dragon. You can see the dragon in the background of one of the earlier photos, and Greg took the close-up below to capture its beautiful design and character.

As I note above, I am excited not only by the quality of the cookware M. Boisserie is making but also by his technique. It is possible to buy brand-new straight-gauge copper cookware from a few makers such as Brooklyn Copper Cookware, Duparquet, and House Copper, but if readers are looking for hand-raised pieces at 3mm, I know of only one other — Rameria Mazzetti in Italy — that is working at this level of the craft. (Please note that there is no functional performance difference between machine-formed and hand-raised copper — the distinction is purely aesthetic.)

If you are interested in adding pieces like this to your collection, I would encourage you to do so soon, while these artisans are still able to make them for us.

How to buy from Atelier Boisserie

As he says above, M. Boisserie conducts his business working in person with customers at his workshop. But he will accept phone or email inquiries (in French) about his inventory and prices and will calculate packing and shipping costs for customers outside France and Europe. (Please note that his prices are based on costs of materials and may vary from the price stickers on his pieces shown above.)

Please note that because he has no online store or electronic payment system, the only form of payment he is able to accept at this time from US customers is a bank transfer.

His email address is [email protected] and his telephone number is +33 0984178566.

Beautiful story about a clearly giant talent who strives to serve his craft and make it evolve. I hear analogous harmonics to talented makers of musical instruments who, “just hear what the materials want to sound like”. Thank you Professor Boisserie for making art in the face of corporate quality reduction. Bravo!

Phil, I am so glad this post resonated (heh) with you!

Wow, loved every bit of this. Thank you for posting!

Cameron, thanks for your kind words — I am so grateful to Greg M. for his idea to profile M. Boisserie, his thoughtful interview and transcription, and the lovely photos that bring us inside the workshop. Thank you, Greg!

It was a great pleasure and honor to contribute to the site in this way, however, I must point out that the interview questions were created by VFC, not me. Good questions elicit good responses.

Mr. Boisseries professionalism and humility throughout the process shined as brilliantly as his copper!

The thanks goes to our our dedicated blogger and Mr. Boisserie.

Absolutely admirable what Monsieur Jean Boisserie has been doing for decades. At the same time, it would be a shame if his knowledge and experience were not preserved and passed on. It is a pity that it is apparently impossible or insufficient to place craftsmanship under the protection of the UNESCO World Heritage. But let’s rejoice in the products we can still acquire from this master coppersmith and in this great report. I am especially pleased to learn that it is undoubtedly possible to form even 3 mm thick copper sheet into a sauté pan and the like using purely handcrafted methods. I am grateful that VFC reminded us at this point of Rameria Mazzetti (Bottega del Rame, since 1857) in Montepulciano (Siena, Italy), where work is done in a similar way. Thank you!

Martin, I agree with your sentiment. But even if there is no large-scale formal preservation mechanism for this craftsmanship, we can each do our part by buying and keeping these pieces for the next generations.

What a wonderful story told here! Many thanks to VFC, Greg Morain and especially Monsieur Jean Boisserie for conducting this awesome tour of this master craftsman’s shop.

This is great! I love seeing and learning about coppersmiths at work. Thank you so much Greg M. and VFC for sharing!

Great story! I really appreciate Greg Morain’s interview with Monsieur Boisserie and VFC for offering this wonderful treat. More than anything, it happily solved a long standing mystery. When I looked closer at Monsieur Boisserie’s very stylized stamps on the pans in his shop, I finally got an answer when they matched what is stamped on the side of my saucepan. Until now, I couldn’t make sense what it said, that is, “Boisserie, Jean”. It also has the same beautiful hammered effects, beveling, and flattened rivets. In addition, there’s a fine dot on the bottoms’ center where he must have used a scribe.

Thank you again for this wonderful article!

John,

That is a very cool story. I am glad your mystery was solved.

Thanks for sharing.

Greg

Well, he can get them round without a compass; his pots have a distinctive groove in the inside corner; his rivets are flat on the inside; and his martelage is hammer marks. I am of the opinion, the compass mark is more common in shops that sometimes make copper pots.

An expert can just make a round bottom and raise a pan by hand with few tools. I watched a video of Japanese coppersmith doing just what he does. And they really just hammer a flat piece of copper up from the bottom into shape. This wasn’t a skill one learned in a week, but trained to do over many years.

I think the groove on the inside corner says hand raised pan. Otherwise the inside corner will be rounded in an even arc of even thickness. It’s the one angle the coppersmith has to work the most.

I was very impressed by the craftmanship described in this post so I recently purchased a 28 cm saute pan from Mr. Boisserie. What this artist does with a flat sheet of copper shaped only with his hands and his array of hammers is amazing! I was very impressed with this pan and will be using it with pride on my stovetop.