This is going to be complicated.

Mauviel is perhaps the most prolific French copper cookware manufacturer of all, or at the very least the most prominent in the US market. And yet for the first 150 years of its existence, Mauviel was virtually anonymous — an artisanal workshop in Villedieu-les-Poêles, in the words of its current president, that transformed in the 1960s into the premier supplier of French copper cookware in Europe and the US but that didn’t stamp its own name on its copper until the beginning of the 21st century.

This post is lengthy and I’ve divided it into sections.

- 1850 to 1940: Artisanal Mauviel

- 1940 to 1962: The post-war period

- 1962 to 1985: Opening the US market

- 1985 to 2000: Copper, tin, nickel, and steel

- 2000 to 2007: Yet more steel

- 2007 to 2011: Mauviel 1830 and the M’ series

- 2011 to present: The M’150/250 series

The last section, Design iterations, 2007 to present, is an omnibus section for stamps and handle changes from 2007 to the present day.

This took me a while to write because I kept heading down rabbit holes into different areas of research. This post will focus on stamps and photos of copper, but there are three five spin-off posts that may also be of interest to you.

- The importance of being Ernest Mauviel is an exploration of the history of Mauviel and the family members who lead the firm over time.

- Cupretam, Cuprinox, and Cupronil covers Mauviel production from 1985 to 2007, a particularly confusing period with three product lines and multiple sub-variants.

- How to tell nickel from stainless may help you visually distinguish these two types of pots in photos.

- Counting rivets focuses on Mauviel’s process of redesigning handles from three to two rivets.

- The demise of Mauviel’s cast iron handles looks in depth at when and why they phased out cast iron.

As always, if you can offer me corrections, amplifications, and examples of things I’m missing, I’d be grateful for a comment or an email. And with that, let’s get started.

1850-1940: Artisanal Mauviel

Yes, you read me correctly — I believe the “Mauviel 1830” we know today began not as “Mauviel” and not in 1830 but instead as Mauviel-Tétrel in 1850, and I discuss my reasons at length in my post on the elusive Ernest Mauviel. (End of rant.) In 1880, Mauviel-Tétrel was renamed Établissements Mauviel-Gautier Frères, a name it maintained until the 1940s. The company supplied restaurants and industry (and, incidentally, copper pots and pans for the Titanic that were recovered and are now on display at National Geographic). Notably, Mauviel-Gautier Frères manufactured pots for the Grands Magasins Du Louvre — beautiful pieces with custom handles, showcased in Mauviel’s Masterpieces: Copper at the Grands Magasins Du Louvre, Paris. They made these pans from about 1880 to the 1920s.

The company supplied restaurants and industry (and, incidentally, copper pots and pans for the Titanic that were recovered and are now on display at National Geographic). Notably, Mauviel-Gautier Frères manufactured pots for the Grands Magasins Du Louvre — beautiful pieces with custom handles, showcased in Mauviel’s Masterpieces: Copper at the Grands Magasins Du Louvre, Paris. They made these pans from about 1880 to the 1920s.

There are contemporaneous documents mentioning the company by name as late as 1939 but I have had very little luck finding records during World War II. In any event it appears that Mauviel-Gautier Frères was one of several small chaudronneries in Villedieu (among cohorts Eugène Lecellier, A. Lefèvre, and Villain-Havard Frères). I call this Mauviel’s artisanal period because that’s how Valérie Le-Guern Gilbert, Mauviel’s president, described it in an interview: “Until the 1960s, [Mauviel] was a rather artisanal workshop.” If it’s good enough for Valérie, it’s good enough for me.

Mauviel-Gautier products stamped as such from this period are hard to find. I have found one item that I think is from this era and quite possibly pre-1900. This old-style colander has hand-punched holes and a dovetailed basket — this is a very old piece.

1940 to 1962: The post-war period

The war was devastating for France, and Normandy suffered greatly. Villedieu-les-Poêles was spared catastrophic physical damage but the wartime demand for copper left sky-high prices for coppersmiths and buyers alike. Armand Mauviel had taken over the firm in 1940 and was left the unenviable task of rebuilding the company in this new post-war economy.

Stamped copper from this period is hard to find, but I found one pan that I suspect is from this era. The stamp says “Mauviel Villedieu” with the initials “A.M.” inside an oval cartouche, presumably for Armand Mauviel. (Also note the absence of the “Made in France” stamp that came into use in the 1970s or so.) This piece is also stamped “WL,” for Wagons-Lits.

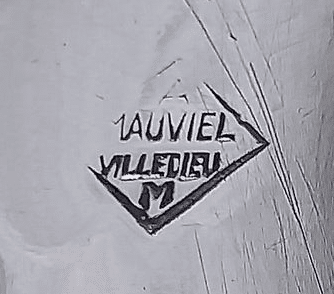

While copper was expensive and scarce, Armand Mauviel had the idea to convert the production lines from copper to aluminum, which was much less expensive and easier to source.This aluminum sugar pan has a diamond-shaped stamp reading “A.M. Mauviel Villedieu” that I believe is from this product line.

Mauviel’s aluminum pans are dead ringers for Mauviel copper because they were made the same way. You can occasionally find these vintage aluminum pots and pans on eBay: they look like Mauviel copper but in black and white. I adore them. I own an aluminum stewpot stamped for Matfer for which I have an inexplicable attachment, and I’m fairly certain it was made by Mauviel.

1962-1985: Opening the US market

According to Valérie, “Armand Mauviel, my grandfather, met our first American client in the 1960s.” That American client would have been Chuck Williams, whose visit to France in 1953 inspired him to open his first kitchenware store in Sonoma in 1956. In 1959, Williams returned to the Dehillerin store in Paris to source kitchenware and learned that the copper pots and pans came from Villedieu-les-Poeles, so he went to Villedieu and met Armand Mauviel. US interest in French cooking and cookware was a huge opportunity for Mauviel and Armand seized it. The two men forged a formidable retail partnership and Mauviel exported its first copper to Williams-Sonoma in 1962.

During that period of time, some 80% of Mauviel’s products were for restaurant supply and the remaining 20% for home cooks. The restaurant supply would have been direct sales or through the Dehillerin store in Paris; a substantial portion of that home market would have been exports to Williams-Sonoma, which sold exclusively to home cooks and high-end chefs, but there were several other US stores that imported Mauviel. I have an ongoing effort to catalog these stores and their custom store stamps so that you can recognize Mauviel work under another name.

Mauviel’s tin-lined copper pieces were available in two gammes (product lines).

- Sur table, “for the table,” was 1mm to 2mm thick in smooth finish. These pans were intended to carry already-cooked food from kitchen to table and provide a beautiful presentation.

- Extra-fort, “extra strong,” was 2mm to 3.5mm thick (or thicker) in hammered finish. These pans were intended for cooking use.

Note that there can be considerable variation in the thickness of extra-fort pans. (Even Mauviel’s current online retailers provide a range of thicknesses for pots in the same product line.) This can be frustrating for buyers, and if thickness matters to you, I encourage you to get a commitment from the seller so you can avoid disappointment.

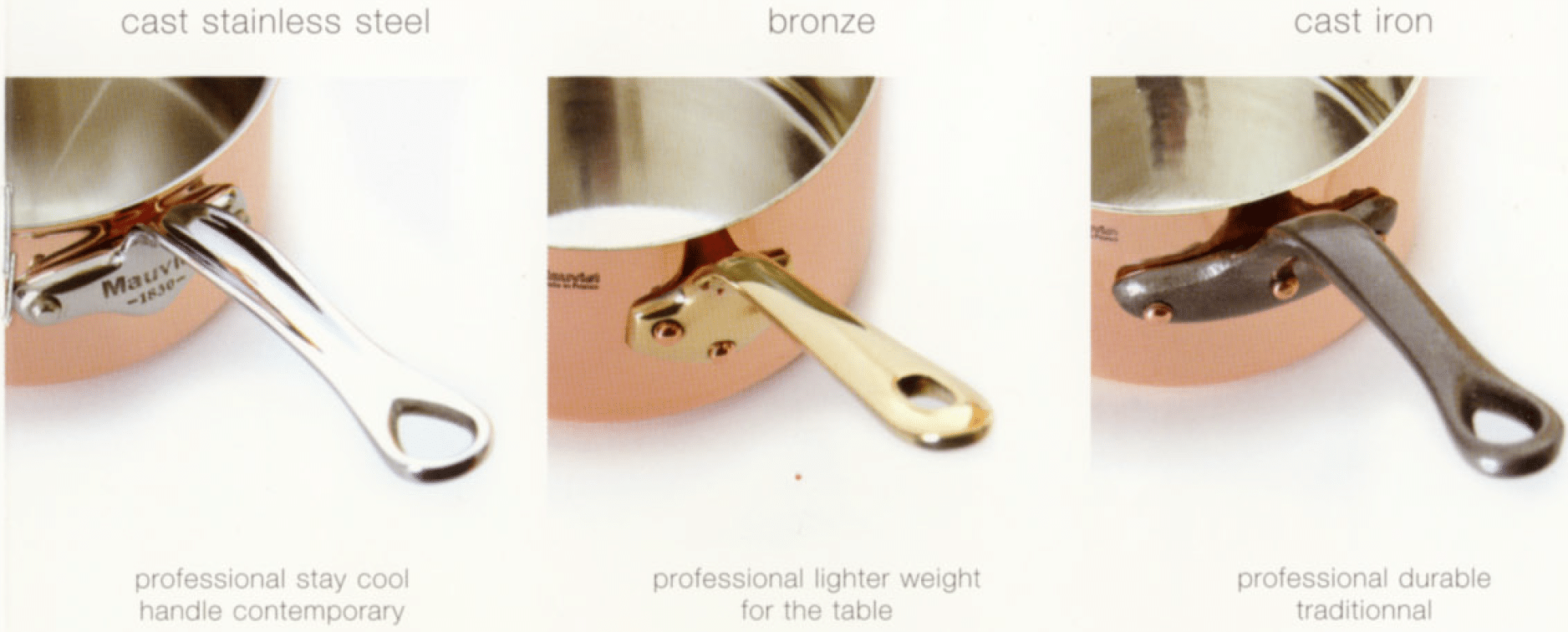

Handles could be either brass or cast iron, depending on what the conventional wisdom decreed was best for the intended use of the pan. Brass heats up quickly with the copper body of the pan while cast iron is slower to heat up and can be more comfortable for bare hands. The broad loop handles on rondeaux, stockpots, stew pots, and other squat pieces were brass, as Mauviel presumes the cook would set the pot in place and not move it very frequently. But an extra-fort sauté pan, saucepan, or skillet would benefit from a long iron handle to stay cool as the cook grabbed it to stir, flip, or transfer food.

The exceptions were sur table pieces, which had brass handles. (The French word laiton means brass or bronze, and you will sometimes see Mauviel say these handles are “bronze” when they are actually brass.) These 2mm or thinner items were not intended for the stovetop at all, and so heat resistant handles were not a consideration.

Though the majority of Mauviel copper left the factory under another name, I did find examples of Mauviel stamps that I believe are from the 1960s to the 1980s. My guess is that these were sold at Villedieu at Mauviel’s factory store; the oval stamp looks earlier to me, as it recalls Mauviel’s earlier cartouche stamps, while the text-only stamp looks more modern in the all-text style of Mauviel’s store stamps of the 1980s to 2000s.

1985-2000: Copper, tin, nickel, and steel

Armand Mauviel retired in 1974 and passed control of the company to his son Gérard and his son-in-law Jean-Marie Le Guern. According to Valerie le Guern-Gilbert, “My father, Jean-Marie Le Guern, has developed a more industrial orientation and worked on international export.” Within a few years, Mauviel began expanding its product line beyond tinned copper and into new materials, and I mark this period as the beginning of the modern era for Mauviel.

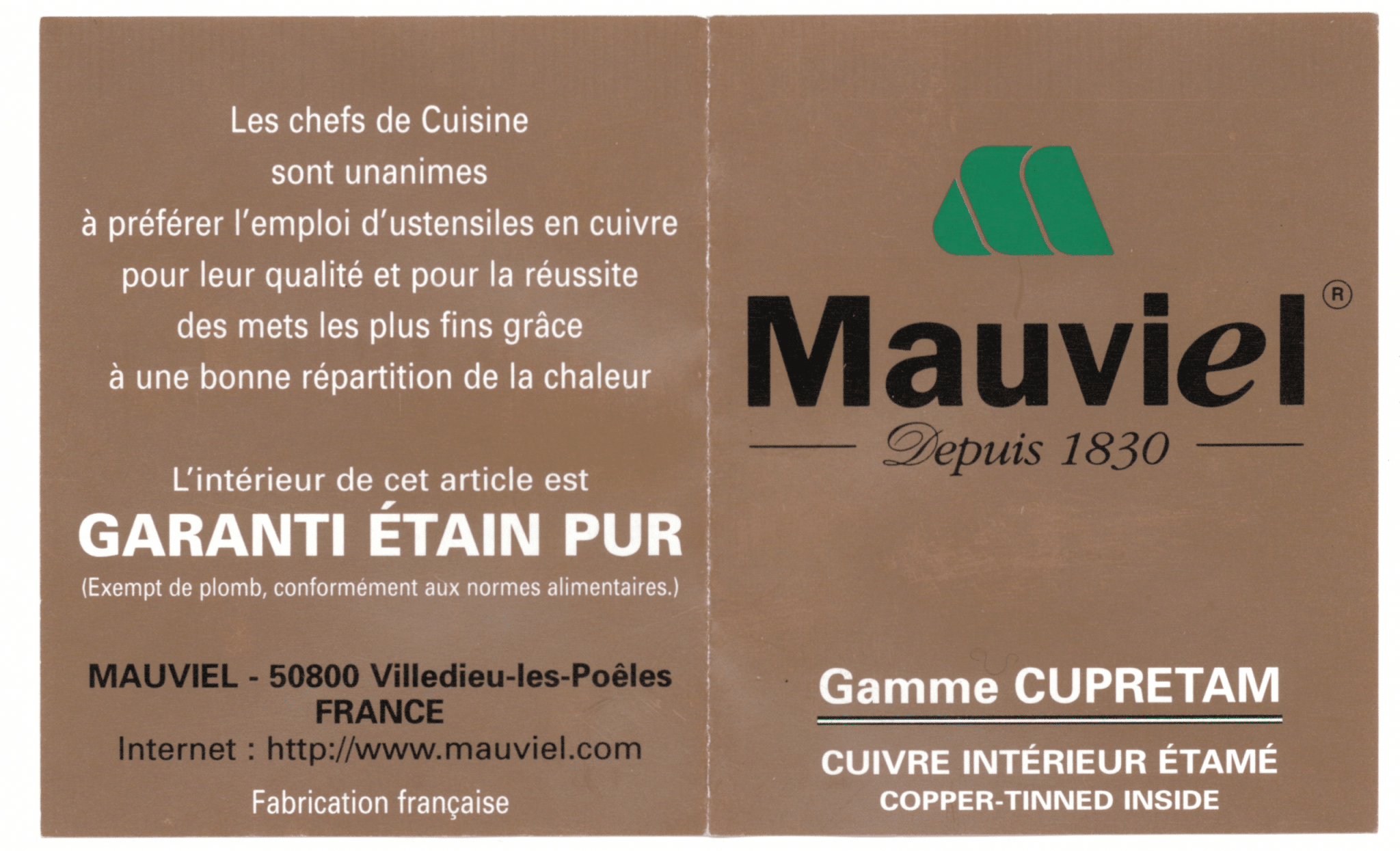

Mauviel had always made tin-lined copper and by 1985 they had added nickel-lined copper as well. This necessitated new product names: “Cupretam” for the tinned copper and “Cupronil” for the nickeled. Cupretam continued in hammered extra-fort and smooth sur table lines. Cupronil pans were made for only about a decade and are more challenging to find (not least because many people fail to recognize them as nickel), but it appears that Mauviel produced Cupronil in sur table (2mm or less) and extra-fort grades up to 3.5mm (sometimes more), always in a smooth finish.

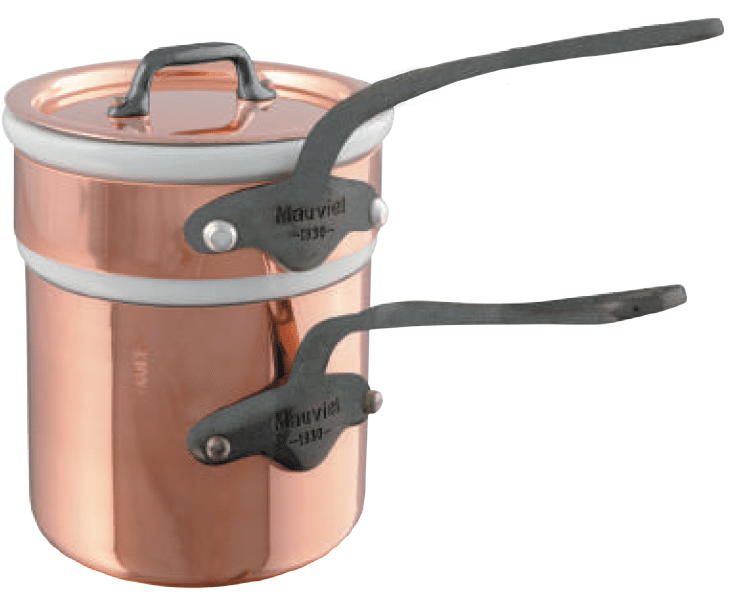

Jean-Marie Le Guern began working on a copper-steel bilaminate in 1989 and in 1995 released the Cuprinox line. (I cover these three lines in greater detail in their own post.) Cuprinox was available in the same two thickness grades: sur table was 1.6mm to 2mm thick with brass handles, while extra-fort was 2mm to 2.5mm thick with cast iron handles. Unlike tin- and nickel-lined copper, Cuprinox never exceeded 2.5mm in thickness.

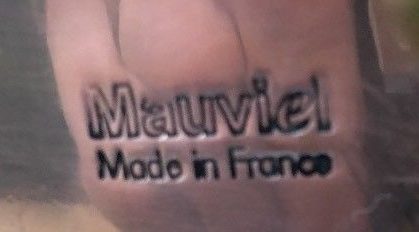

During this period, Mauviel developed a more modern logo: the word Mauviel with an italicized e. This logo shows up on paper product inserts and stamped on pots. While Mauviel subsequently changed its logo in 2007 to “Mauviel 1830,” the italic-e copper stamp stayed in use for several years.

2000-2007: Yet more steel

Starting around the year 2000, Mauviel expanded the stainless-lined Cuprinox series from two to four lines.

- Extra-fort became simply Cuprinox, 2.5mm thick with cast iron handles

- Sur table became Cuprinox Sur table, 1.6mm thick with brass handles

- Cuprinox Gourmet was the first new line, 2mm thick with cast iron handles

- Cuprinox Style was the second new line, 2mm thick with a pouring lip and stainless steel or cast iron handles

Cuprinox Style is the most distinctive of these, with a pouring lip and the option for stainless steel handles. I’m very curious about this handle design. Was Mauviel re-using the casts for its iron handles, so that the steel handles looked exactly the same? Or were the handles a new design, perhaps borrowed from Mauviel’s stainless steel Induc’Inox line? If you have any of these lying around, please tell me what they look like.

Cupretam remained the same — sur table in 2mm or less, extra fort from 2mm to 3.5mm.

2007-2011: Mauviel 1830 and the M’ series

Valérie Le Guern-Gilbert, daughter of Jean-Marie and granddaughter of Armand Mauviel, became president of Mauviel in 2006 and began a decade of design and merchandising changes across all the product lines.

First, Mauviel changed its brand name to Mauviel 1830, a deliberate move to evoke history. (You already know how I feel about the whole 1830 thing.) Then, Mauviel renamed all their product lines under a new M’ system of nomenclature.

- Tin-lined Cupretam became M’tradition.

- Stainless-lined Cuprinox became M’héritage.

- Specialty copper tools for patisserie and confectionary became M’passion.

- Tinned copper and aluminum barware became M’30.

Mauviel also revamped the stainless-steel Induc’Inox line and released several new lines of steel and aluminum cookware. (I don’t cover this stuff, but here are the names and types.)

- Stainless-steel Induc’Inox became M’cook and M’basic.

- The new M’stone line was made of black non-stick anodized aluminum.

- The new M’pure line was made of solid aluminum.

- The new M’steel line was made of carbon steel.

- The new M’plus line encompassed accessory products such as racks and stands.

This explosion in product offerings was accompanied by a major website overhaul. The prior Mauviel site was replaced in October 2007 with a placeholder site with sparse descriptions of the product lines and an apologetic “Site under construction” banner. It looks to me that the rebranding effort took over a year; the 2008 catalog — the first that Mauviel produced, to my knowledge — is a spartan affair that doesn’t mention any of the new products. Instead, it showcases surface finishes and handle types as shown below, with a smattering of evergreen tin-lined “specialty products” as eye candy.

In January 2009 the website redesign was complete and Mauviel’s French site (mauviel.com) relaunched with the new Mauviel 1830 branding. The US site (mauvielusa.com) followed in December 2009, but the new product names took some time to percolate through to Mauviel’s US retail partners. Pre-boxed sets of M’héritage copper pans showed up at Fante’s (www.fantes.com) in August 2009, but individual pots were still described without using the M’ names well into 2017. For its part, Williams-Sonoma ignored this terminology completely, as will be discussed below.

But the changes at Mauviel went deeper than just product names. Mauviel seems to have decided that home cooks weren’t much interested in tinned copper. While Mauviel continued to manufacture a full range of M’tradition tinned saucepans, sautés, rondeaux, and so forth, these products weren’t visible on Mauviel’s website or in its retail catalogue (with the one exception of the 2016 catalog). The tinned copper M’tradition line as advertised on the Mauviel website and catalogs offered only specialty items like daubières, large stockpots, bains maries, and so forth (again, with the single exception of the 2016 catalog). If you wanted to cook on tinned copper at home, you had to go through a retailer such as Williams-Sonoma or Dehillerin.

Mauviel’s retail focus seems to have been set squarely on streamlining and promoting its stainless-steel lined offerings. Cuprinox Gourmet (2mm with a straight edge and cast iron handles) was eliminated. The Cuprinox Style and Sur table lines were folded into the M’héritage designation and became options without distinct names:

- “Cast Iron Handles, Straight Edges, 2.5mm Thick Copper.” This is the original extra-fort Cuprinox, the top of the line stainless-steel series.

- “Cast Stainless Steel Handles, Non-drip Edges, 2mm Thick Copper.” This is the former Cuprinox Style with the pouring lip, but the option for cast iron handles has been removed.

- “Bronze Handles, Straight Edges, 1.2 to 2mm Thick Copper.” This is the former Cuprinox Sur table line.

From 2009 until 2011, Mauviel’s strategy to communicate the new M’héritage lines to the consumer (and retailer) was to keep it simple and focus on the handle material. The product lineup consisted of the three configurations of pan as shown below. If you wanted cast iron handles, it was going to be 2.5mm. If you wanted stainless steel handles, it was 2mm. If you wanted brass handles, it was 2mm or less.

And of course, if you wanted tinned copper, good luck with that. Maybe Williams-Sonoma or Dehillerin could help you out.

2011 to present: M’héritage 150/250 series

In 2011, Mauviel expanded beyond the three M’héritage variants to offer more choices of handle and needed a better way to describe these options. They came up with a system of numbers and letters that would indicate a pan’s thickness and handle material.

The “M’héritage” name, or sometimes simply M’, would be followed by a number.

- 150 means the pot is 1.5mm thick.

- 250 means the pot is 2.5mm thick.

After the number is a letter.

- b indicates a brass handle.

- c indicates a cast iron handle.

- s indicates a polished stainless steel handle.

A “M’héritage 150b” or “M’150b” pan was 1.5mm thick with a brass handle, while a “M’héritage 250c” or “M’250c” was 2.5mm thick with a cast iron handle. (You may see some resellers forgo the M’ part and just call them 150b or 250c or whatever.) I think the numbers and letters make sense, but “heritage” and “tradition” have no obvious semantic mapping to stainless steel or tin and I find it hard to keep them straight. But what do I know? I’m just a person who buys a lot of copper cookware.

Williams-Sonoma’s variations

Williams-Sonoma seems to have paid only glancing attention to Mauviel’s evolving naming conventions. They never used M’héritage or M’tradition names on their website, preferring instead to use their own names as follows.

- Mauviel M365 was 1.5mm thick with polished stainless steel handles, equivalent to M’héritage 150s.

- “Mauviel copper” — an exclusive line — was “heavy gauge” 2mm with a pouring lip and brass handles, reminiscent of Cuprinox Style. There was no thickness equivalent in Mauviel’s M’150/250 series, so it looks like Williams-Sonoma worked with Mauviel to continue the 2mm thickness as an exclusive.

- Mauviel M’Pro or Professional was 2.5mm thick with cast iron handles, equivalent to M’héritage 250c.

On March 1, 2014, Williams-Sonoma abandoned the “M365” and “M’Pro” designations for the equivalent “M150s” and “M250c” terms, but still without the M’heritage moniker. But “Mauviel copper” — exclusively 2mm thick — stayed.

Dehillerin’s variations

Dehillerin is a serious store for serious people. Dehillerin will assign the correct names and descriptions to kitchenware items. Mauviel copper pans that are lined with stainless steel are called Cuprinox. That was the way it was in 1995 and that is the way it is now.

Design iterations, 2007 to present

Stamps

For the copper stamps, Mauviel has kept the same italic-e logo from the 2000s era with either “France” or “Made in France” as shown below. The stamp could be vertical or horizontal and I have yet to detect a significance in the orientation. Pans with stainless-steel handles already have “Mauviel 1830” embedded in the baseplate and seem only to have “Made in France” stamped on them.

Between 2014 and 2015, Mauviel began to migrate from the Mauviel italic-e stamp to the “MAUVIEL 1830 France” stamp. It’s difficult to see in the catalogs unless you spend as much time as I have peering at the pixellated photos, but it’s there.

Ironically, the clearest early photo evidence I have of this from Mauviel is from the back cover of the 2015 catalog. The photo shows a stack of pan bodies, presumably from the Mauviel workshop, that have been used as practice for the “MAUVIEL 1830 France” stamp. (The large single word “FRANCE” is used on the M’minis series, in case you’re wondering.) I also found some product listings from the current (April 2019) mauvielusa.com website where the “MAUVIEL 1830 France” stamp is clearly visible.

Rivet reductions, 2014-2015

I have a separate post with more detail on this because this is an issue worth discussing in depth and I’m trying to keep this post focused. But Mauviel has recently made a series of design changes to its handles that reduce the number of rivets. While this might not be a big deal for steel-lined pans with steel rivets, it may be a big deal for pans with copper rivets. Here’s what’s going on.

From 2014 to 2015, Mauviel updated its three-rivet “b” (brass) handles to two-rivet “b2” version. The new handles have “Mauviel 1830” imprinted on the baseplate.

From 2014 to 2015, Mauviel made additional unannounced changes to the design of its cast iron and brass handles to reduce them from three rivets to two. The overall shape of the baseplates does not seem to have changed significantly.

Cast iron handles to “electroplated cast iron finish,” 2015-present

This one is a doozy. From 2015 on, Mauviel stopped using cast iron handles. Instead, they took the same stainless steel handles in use for the 150s and other steel cookware lines and electroplated them with a matte black finish. This finish is referred to as “iron electroplated finish” and the handles are denoted c2. These handles are still making their way into the hands of consumers but early reports on Chowhound are that the “iron” finish can rub off.

Conclusion

This post has taken me three months to write and 100 revisions. It has spawned three five spin-off posts. I really hope this is helpful information to you to help you figure out what you’re seeing online.

And as always, please help me make this more correct, for others like us who want to learn and make good buying decisions. Leave a comment or email me — thank you.

Resources

I pulled together all the Mauviel catalogues I could find. Here they are by year. The retail catalogs are what’s available for the home cook market; the food service catalogs are far more extensive, but many of the products can only be bought through commercial restaurant supply.

Sources

I’m indebted to a series of articles that filled in a lot of historical details on Mauviel.

- “On cuisine dans du Mauviel depuis 1830,” 03 October 2013.

- “La cuisine du monde mijote dans du Mauviel,” 19 January 2012.

- “Cuivre. La manufacture Mauviel, de la tradition à l’innovation,” 24 May 2017.

- “Dinanderie. A Villedieu-les-Poêles, Mauviel 1830 s’adapte et exporte,” 26 December 2016.

- “Mauviel ou l’art de travailler le cuivre culinaire,” 20 July 2015.

- “Qualité et sagacité, ingrédients de la longévité de Mauviel,” 01 February 2012.

- “Mauviel 1830: Z nadšení se rodí výjimečnost,” 08 October 2016.

- “Les boulettes marocaines de Valérie Le Guern Gilbert,” 30 January 2017.

I relied on the Internet Wayback Machine to look at archived websites for Mauviel, Williams-Sonoma, Fante’s, and other sites that I mention. This is how I got an idea of how Mauviel’s products were represented. This is not a perfect way to understand the history of this industry but it’s a start.

Corrections

Well that didn’t take long. I think I figured out what the “mystery pan” is with the MAUVIEL 1830 France stamp and the strange handle: a new line called M’3S, triply copper/aluminum/stainless that was released in late 2018. I’m not 100% sure that it is, but a bunch of these pans have come onto eBay lately, and one seller says that’s what it is. So that explains the different handle style — it seems to be recycled from Mauviel M’360, a European line of all-stainless cookware circa 2012.

Here’s the mystery pan:

Also, I learned a little more about the timing of Chuck Williams’ visits to France in the 1950s, and corrected the dates accordingly.

In late May 2019 I amended the section on artisanal Mauviel to mention the series of pans they made for the Grands Magasins Du Louvre.

Thisi is infomation of mystery pan

I’m Japanese

I have one saucepan (M150s) from Japan yahoo auction

previous owner buy from Amazon 2017

https://i.imgur.com/6rM0274.jpg

and two fry-pan in Japan Yahoo auction and mercari

https://i.imgur.com/5MWDQHW.jpg

Hi tombook! Thank you for that information and photos! On the box label it says “MONTURE 360” or “MONT 360” which I translate as “mounting,” referring to the style of the attached handle. So I interpret that label as saying, “Mauviel M’150 with the handle style of the 360 series.” Very interesting that they’re offering this handle style in addition to the modern “MAUVIEL 1830” two-rivet style. Thanks again for this information — it’s really helpful!

Hello! Can you help me… I am trying to see what the stamp STL MEANS WITH MADE IN FRANCE- is this mauviel- it looks like a two bottle champagne cooler with divider- tin or st steel? And brass handles. It is hammered copper…

Hey there K! I can help you right away with this — “STL” is for Sur La Table, the cookware store, and this is almost certainly made by Mauviel. I have one just like it with the removable divider. It works really well but it does “sweat” a lot so I use mine on a tray.

Absolutely phenomenal piece of reference work, thank you.

I found your article because I was looking for ways to spot an authentic Mauviel item. I’ve been searching ebay for older three rivet pieces and have no idea if they are authentic Mauviel or not as many are not marked.

I just purchased my first copper pot set – the M’Heritage 250b 12 piece set from Cutlery and more after many hours of looking at different manufacturers of copper cookware. I was disappointed to find that they removed a rivet to save some $$. I read that the forge for the cast iron handles burned down hence the change and Williams Sonoma was left with no stock so they rushed and used the now awful painted fake cast iron handles. They need to bring back the 3rd rivet for tin lined/copper riveted pans without question. Stainless appealed to me as there are no re-tinners in California and worried down the line it would be even harder to find someone. I couldn’t even find many tin lined Mauviel pots. Now I wish I found you sooner and learned about Dehillerin! :/ I don’t think that I will return the set, but I am hooked now on copper and plan to get a few more vintage pieces.

Evelyn, the Mauviel 250s are great pans — I’m sure you will get a lot of use out of them. 2.5mm bimetal is top of the line for copper-stainless pans for a reason. The rivet and handle changes diminish collectibility in my opinion, but I don’t think there’s any difference in how the pans perform before and after the change. Enjoy them and use them, and you may find the opportunity to add to the team with some additional vintage pieces for a different experience!

Hi!.

have you ever seen a 3mm stainess stew pot with brass handles? I believe it was released in early 2000’s at SLT. I am just trying to confirm that it exists and perhaps a model # it might be 11″ or 12″ wide. Not even sure if mauviel made any stew pots wider than 11″ that are also stainless.

-joe

Hey Joe! May I ask you to be a little more specific? Do you mean a stainless steel pot, or do you mean a copper pot lined with stainless steel?

Hi

Copper pot lined with stainless. it’s 3mm thick and appears to be a stew pot. I just never seen a 3mm stainless as i thought 2.5mm was max. 🙂

Hi Joe! Ah yes, the 3mm thick stainless-lined unicorn… I have heard of such but never held one in my hands. Every 3mm pot I’ve thought was stainless-lined has proven instead to be nickel-lined. Do you have photos of this fabled beast? Or even better, do you have it so you can measure it and test the lining for nickel?

Hi. I don;t have a way to test it nor I actually have to pot. I spent a lot of time reading your blog and I love it, btw. I think the e in mauviel is italized, so it’s probably 2000+ and younger, and afaik nickel was probably stopped being made by then? I don’t know if my fried is willing to part with it, but Ill try to barter.

BTW, maybe you could help me out. Are you are of ANY steel lined rondeaus or stew posts that are at least 30+ in diameter.. something around 32-36mm (ideally around 12-14cm tall and about 9-11liters)? My initial research showed nothing but I also know they make a lot of pro stuff that is rarely listed or shows up, so I thought i’d ask!

Joe, let me know if you can get a closer look at your friend’s pan!

As to your question about restaurant-scale steel-lined Mauviel pans, I took a look around and I can’t find specifications for rondeaux or stewpots greater than 28cm diameter. Readers, have any of you come across 30cm+ Mauviel-made steel-lined pieces?

30 and 32cm stewpans and rondeaus are certainly sizes that might also be used by home cooks. If Mauviel made these in steel lined pans I am sure they would have been listed in their cuprinox line.

I will. it might be a while until I do. I do know that they still make or recently made tin lined ones up to 40cm. the 32cm is M’tradition 2152.32 and other end is 36 and 40

The largest diameters I’ve seen in Mauviel’s catalogs over the past 20 years have been 45cm. But these were rondeaus and stewpots of the Tradition series, i.e. tinned copper. In the Heritage series, stainless steel clad copper, the largest diameter was always only 28cm.

In addition to the series production, Mauviel also offers handmade products, but I suspect that this offer does not refer to the Heritage series.

Joe, it might be best to contact Mauviel directly with your question ([email protected])

The Dehillerin catalog for 1999 listed tin lined rondeaus and stewpans (which I believe were Mauviel) up to 50cm. Going by what Martin wrote these 50cm pans were soon discontinued after 1999. The steel lined cuprinox line only went up to 28cm for these pans.

ty all. that’s exactly what I thought, but was hoping I would be wrong. I just don’t know if I want to go tin and dread of damaging it.

Joe, I started with stainless steel lined copper 25 years ago. Over the years, this stock decreased somewhat and more and more (vintage and antique) tin-lined copper pans were added. I initially had the same concerns as you, but if you love your pans and treat them as recommended, the advantages outweigh the disadvantages. The aesthetics of the old pans are something very special to me that I don’t want to do without. But the modern variants are also good and tolerate a more robust treatment.

Indeed! The main reason I want a 32 or 36cm pan is to make tomato sauce or bolognese or other sauce in bulk. so my only concern would be the initial frying / browning, but i dont expect it to go over 400f, so tin should be fine… it’s just a concern, vs a fear. i have a falk 8.4qt stew pot and it works well for me, but it doesnt reduce and brown as well as it could be since it’s a bit narrower than 32 or 36mm would be.

the rondeau/stew pot in q is this ebay item. 293625245223 apparently my friend wasn’t being clear. it’s not his but someone in his family. so, i actually would need to buy it. and the pan raised some concerns with me because they sate it’s SS, 3mm thick and 10qt. all of those are not what I been reading. it seems 9.4qt, 28cm is largest for SS, but also 2.5mm is.. they clearly show 3mm thickness, so something is afoot.

it also made me wonder if there was some custom made pans for hotel industry in SS, with larger size but then it would be barely larger? just confusion all over

Joe, there’s a straightforward solution here: ask the seller to test the lining for nickel.

I did earlier and seller said it’s steel. They looked through magnifying glass and are sure. Considering they have 100’s of copper pieces… i have to trust it If i understood your hint through, that there are def nickel lined marlerger than 28cm stew pots or rondeau’s available, or to be precise were available?

tia!

Joe, that pan on ebay is 28cm so it doesn’t seem to fit your interest in a 32 or 34cm pan. If you don’t mind going with tin lined rondeau or stewpan and you don’t care if the pan is vintage you might want to check out the Dehillerin website. The prices for new Mauviel pans are quite reasonable compared to those here in the states (if that is where you are located). I believe the tax they show in the checkout does not apply if they are shipping outside the EU. One thing I have seen with Dehillerin is if you send them just a question you might very well get no answer. If you submit an order, that is no problem.

Stephen,

TY for your reply. I imagine I would have to do that. I somewhat wanted to avoid it, obviously, but it doesn’t seem like I can do that.

tyvm!

It has often been pointed out that information on the material thickness of copper is often inaccurate and excessive. If you measure the wall thickness with a device like the one mentioned in the ebay offer, you cannot get an exact value because the device has a relatively wide measuring surface / support. Due to the curvature of the wall, this inevitably results in an error that can easily amount to 0.5 mm. VFC has already described this problem in detail and therefore recommends other measuring devices.

Joe, you need to know for yourself whether you are a copper lover who appreciates the special qualities of this material and is willing to pay the enormous additional costs compared to a pot made exclusively of stainless steel, which may also serve your purpose. But if you are passionate about copper, welcome to the club!

TY very much. Basically, i feel like your answer really clarified for me, that the pot is nothing special, just a normal 15 year old SS stew pot that’s 2.5mm and 28cm in diameter, which is readily available now.

I am not sure if I am a copper lover, per say, but I def appreciate it’s cooking properties. Only time will tell, of course 🙂

I have a photo copy of an early 1980’s Mauviel catalog, if you would be interested in seeing this let me know. Also, an important US importer of Mauviel was Charles Lamalle of NYC. I bought several pieces from Mr. LaMalle in 1979. Still using them. Like most things, Mauviel isn’t what it used to be. I will stick with my “ old” pieces. Thanks, Michael Balin

Thank you Michael! If it’s not too much trouble, I think we all would love to see it whenever you get a chance to scan it 🙂

Thank you for your interest. I also have a Dehillerin catalog from 1984, and Charles F. Lamalle’s item list from 1988.Please send me an email address, and I’ll scan the catalog/ as long as my cranky old scanner will cooperate. The Mauviel pages are very poor copies, unfortunately.

sure thing

joeolerud at gmail dot come

ty

Good Morning Joe/

As the photo copy of the Mauviel catalog is so poor, it might be better if I just sent this to you by snail mail.if you are interested, I’ll include Charles F. Lamalle’s French copper pages, circa 1980’s, and as an added bonus, the Catalog of E. Dehillerin from 1983.,plus an invoice of a purchase I made from Dehillerin in 1984.

Please provide your mailing address.

Please return all to me when you have finished with these. Sorry, I haven’t noticed any “makers Marks” anywhere in any images. I’m glad to know that there are others out there who are interested in this great cookware.

Best Regards, Michael Balin

Michael,

thank you for your very kind offer. May I request that you send it to VFC (this forum owner), so they can try to somehow post it for everyone’s enjoyment? I would never want to be this selfish 😀

TYVM, again 🙂

Michael, I’d be grateful for any catalogs in whatever format you can share them — hard copy included! — and I’d be happy to generate a digital version to share on this site. If you’re amenable to this, send me an email. Thank you! VFC at vintagefrenchcopper dot com

Michael was kind enough to send me the hard copies and I have scanned them and posted them to a new “Library” page I made for the site: https://www.vintagefrenchcopper.com/library/

I’ve also added other catalogs I have as well as some helpful links to online research resources. It is a work in progress and I continue to expand it.

If you have catalogs you’d like to share I’d be happy to host the files and make them available, and as with Michael’s documents, you can mail me printed documents that I will carefully scan and return. My sincere thanks to Michael for sharing these with us!

Michael, I’d also be grateful for scans of those catalogs. I use them to research stamps and estimate the age of pieces, so anything you have would be helpful. My email is VFC at vintagefrenchcopper dot com — thank you in advance!

I found a copper wok,stamped made in France,.it has a cast iron handle and 3 rivets.I can’t find another onljne.I’m wondering about the age and which company made it.

Hi Helen! I don’t know much about copper woks but I think they were a fairly recent addition — maybe in the 1990s or even 2000s? Do any other readers know? I’d be happy to take a look at it to see if I recognize the stamp or handles. If you like, take some photos and email them to me at VFC at vintagefrenchcopper dot com. Thank you!

The definitive essay on Mauviel – you are a mine of information VFC, thank you. I am in the process of accurately dating a Mauviel Cuprinox 28cm pan with bronze handles. Wish me luck!

Hi,

After hearing about how the electroplated iron handles have the paint rub off, I became more interested in just stainless steel handles. I see on the Mauviel shop on Amazon that there are a couple of 250s pieces, but I cannot seem to find information on them anywhere else. Are the fake? or discontinued? or perhaps mislabeled? I looked through the last 4 catalogs you posted and do not see them on there (besides the M’Minis or the M’150s). Any help would be appreciated.

Thanks,

Patrick

Hi Patrick,

M’heritage M250S was a cutleryandmore.com exclusive with the same handles as M250C but without the black electroplating and the copper was brushed instead of polished. The last of their stock appears to have sold out this year (2022).

Regards,

Jonathan

Hello VFC

Here is the link to the Mauviel shop in Villedieu les Poeles, there is a little history and the full range of what Mauviel are currently up to on this link! https://www.mauviel-boutique.com/ I especially like the M’Tradition.

Hi Patrick, there was a M’heritage series with stainless steel handles, copper with stainless steel lining 2mm thickness and non-drip edge. I have the brochure.

The elctroplated handles of the M250 series are not iron, but steel.

I’m not sure if Mauviel gave buyers of the Heritage M250 series a choice between cast iron and stainless steel for a while. Have a look at the online shop of Dehillerin, Paris.

Hey Martin, Thanks for your reply! Sorry, for clarification I meant the stainless “electroplated cast iron finish” vs “Cast stainless steel handle with textured matte finish” which I found here: https://www.amazon.com/gp/product/B07YSXXXKP/

That’s interesting about the 2mm M’Heritage. I’ve looked around Dehillerin, buycoppercookware, and a few others. But no one (including eBay) seems to be selling “250S”. I’m afraid this might be a mislabel, and not 2.5mm perhaps 2mm or even 1.5mm. Think I might have to look at some other brands, I’m mainly looking for something with 2.5mm copper, stainless lining, and stainless handles (that aren’t painted black).

Hey Patrick! I see what you mean — that Amazon M’250S item has a matte steel handle that doesn’t appear on the Mauviel online store (mauviel-boutique.com) or Williams-Sonoma. But I doubt that it’s fake — it’s coming from the official Mauviel store on Amazon. I’ve noticed that Mauviel seems to be changing its distribution channels in the US market: mauviel-usa.com and mauvielusa.com are both not functional at this time, and the former Mauviel reps in the US are no longer representing the company. I think Mauviel is focusing on mauviel-boutique.com in Europe and its Amazon store for the US. This may also give Mauviel a channel for products designed for the US market, such as a line of 250S with textured steel handles. After all, they’re exactly what you’re looking for, right? 🙂

It seems very clear that their direction is the consumer market; and that previous standards have been abandoned. If you want « old » Mauviel, I think that the only way to get it, is to buy second hand, when you can find it.

Michael, I certainly share your nostalgia for “old school” Mauviel. I think they are facing huge challenges to their business and making difficult decisions to stay viable. Some of the choices seem well-calculated to expand their customer base — their extensive steel lines are an example of this — but others seem to have been forced on them by events such as the loss of their cast iron handle supplier. I’m just glad that “old Mauviel” is so well-made that it is still showing up on the second-hand market — even people who know nothing about copper can’t help but be impressed by the heavy weight and grace of these pieces, and sense intuitively that they are valuable. That is the kind of quality that lasts.

Interesting. I’ve been wondering where their official website went for some time now, thanks for the link!

Yep, it is exactly what I’m looking for, and it lists it as through their Amazon store. I noticed it is sold through “Cutlery and More” as a reseller, and they only have 1 available. Just seems very curious to me. Their website seems reputable, I just wasn’t seeing any 250S in recent brochures. This (https://www.cutleryandmore.com/mauviel-mheritage-250s/25mm-brushed-copper-skillet-p138523) does say “Exclusive” at the top. Could it have been made specifically for this shop?

As a first purchase, I would just really like to not get duped out of a 2.5mm piece for a 1.5mm one. But, I will reach out to them and see if I can confirm it’s 2.5mm or an exclusive set for their shop. Otherwise, I might have to play it safe and look into Falk or Matfer Bourgeat, which will most likely result in a cast iron handle.

Patrick, I am sorry to say that I don’t really keep track of Mauviel’s current product line. But it is not entirely unexpected to me that Mauviel’s catalog vs website vs retailers are not in sync about products. I have not bought from Cutlery and More before but I have not heard bad things about them — you might search Chowhound and see if readers there talk about it. Another option might be to contact France Corner — they don’t have these pans on their site, but they have been a Mauviel retailer for a long time and might have some insight as to why these textured handles are showing up only with certain retailers. (And they could possibly order them for you.) Whomever you deal with, get the weight of the pieces and compare them to the weights of products on Falk’s site — I have a lot of weights and measures but it’s for tinned stuff, and Falk’s Signature range will be more accurate for 2.5mm steel-lined pieces with steel handles.

Ok, will do. Thanks so much for your help!

New user here and learned a lot on your page. Are all pans stamped? Found a local person selling what seems to be the jelly pot but there’s not a stamp on it. Looks like the one on W-S page. Don’t want to get a knock off.

From my personal experience, not all pans are stamped with the maker’s name. Most of my collection is heavy duty Mauviel, from the 1960-70-80’s time frame; and nearly all of these are only marked “ Made in France”. A few have importers, or dealer’s stamps. For example:

“Williams- Sonoma”, “LaMalle NYCity”,

or “Dehillerin/Paris”.

Christina, welcome — As Michael says, some pieces are and some aren’t! I’m happy to take a look — I’ll send you an email and you can reply with photos if you like.

Michael is right, there are a lot of good quality pans made by Mauviel that left the company unstamped, or received the stamps of the shops that sold them, or just made in France. The decisive factor is the quality of the production and here again the thickness of the copper is decisive, which is easiest to measure using the weight. Many other quality criteria can be found at VFC. For collectors of pans from the first half of the 20th century or even older pans, the stamp is more important, as it is a decisive characteristic of authenticity and increases the value of a pan. Just as a painting by a famous painter increases in value with his signature.

How can you tell the difference between M150c vs 250c? Can you visually measure the thickness? Is there a different number printed somewhere?

hi

yes, you can measure it with calipers or micrometer. and it will be heavier by a good amount.

Hi DC20 — I’m not aware of a different marking on the two product lines. If you had the pan in front of you, you could weigh it — Falk includes reference weights for its 2.5mm bimetal series, so you could look up a Falk pan of similar dimension for comparison — or use calipers as Caesar suggests. But if you are relying on photos, I think you’d need a good clear shot of the rim of the pan to tell. The two pans have the same thickness of steel lining — .3mm — but the visual proportion of copper to steel at the rim will be different. The .3mm of steel against the 1.2mm of copper in a 150 will represent 25% of the total thickness of the pan, while the same .3mm against the 2.2mm of a 250 will represent just 13% of the total thickness.

Hello. This blog and information was very helpful!

I’ve noticed the Dehillerin prices for their “extra thick” copper (as they describe) is much less than at the Mauviel website. I purchased a splayed Saute 6’3″ pan. Copper with tin lining. The tinning seems to be on the top rim as well which is beautiful. But its hard to see the thickness of the copper to verify thats its really thick.

Are the DeHillerin pans the 250 line? On the handle theres simply an “M” and then also the Mauviel 1830 Made in France stamp and the Dehillerin Paris stamp on the sides on the handle.

I’m interested in purchasing more of these, but want to make sure of the above concerns.

Why do they offer some tin lined pans whereas these are hard to find elsewhere?

Thank you in advance!

kevin

You might send Dehillerin a email asking your specific questions. I would suggest-

Are the handles cast iron? What is the thickness of the pans? If you cannot get satisfactory answers, then older pans on the resale market might be worth looking into.Or, go to France, when it becomes possible.Nothing beats putting one’s hands on the goods.

Hey Kevin! I answered your email separately, but to repeat here: M’250 is steel-lined, not tinned. In my opinion the best way to compare tinned to steel-lined pieces is by the mass of copper: M’250 has 2.3mm of copper bonded to .2mm of steel, so a comparable tinned piece would also be 2.3mm. (It’s complicated because the steel lining actually impedes heat transfer a bit, but I don’t even want to try to quantify that!) The tinned 16cm splay listed on Dehillerin right now weighs out to about 2mm based on my comparable pieces, which is a little less mass of copper than the advertised 2.3mm on an M’250. (Keep in mind there is often variation from one tinned piece to the next — the best way to know what you’re getting is to ask before you buy it!)

As to why it’s so hard to find new Mauviel tinned copper, it seems to me that Mauviel is scaling back production of everyday tinned cookware and reserving that time and effort for showcase pieces (daubieres, stockpots, poachers, and the like). Dehillerin, France Corner, and other distributors may be making their way through diminishing quantities of stock on hand. But I am not tracking present-day copper production — you might get in touch with France Corner to ask about what they have available and what they forecast in the future. (I also hear that France Corner has entertained requests to weigh and measure pieces before purchase, which is a very courteous level of customer service.)

Hello Kevin, Mauviel M’heritage 250 is copper with steel lining. If you are interested in copper pans with a tin lining, M’tradition would be the right series. Dehillerin also offers these series. However, Dehillerin uses its own names and the handles of the Dehillerin series with tinned copper are made of brass (bronze). Handles made of traditional cast iron have not been around at Dehillerin for years. The series with stainless steel lining have either handles made of stainless steel or brass (bronze). Dehillerin’s European prices have always been slightly cheaper than Mauviel’s prices, although all of these pans have been manufactured by Mauviel for several decades.

https://www.edehillerin.fr/en/#

Thank you for the excellent education! I happened upon a Mauviel M’Cook B stainless steel saucepan 1.2qt with brass handle, but it is a confusing piece. The triangular handle attachment has 2 rivets with the “M” stamp in the middle The pot is stamped on the side with Mauviel 1830 with Made in France below it. Have you ever seen this? Is it genuine?

Hey Fannie! Unfortunately I don’t know much about Mauviel’s recent-era copper pieces, and even less about the non-copper lines. I’m sorry I can’t be of assistance!

In 2021 Mauviel will replace the M’heritage M’250c series (stainless steel-lined copper, handles made of stainless steel with an iron look) with the new M’heritage M’200CI series. Now with iron handles again, but the wall thickness has been reduced to 2 mm. Obviously, customers were asking for the traditional iron handles again. However, the 0.5 mm lower wall thickness is regrettable. Probably an economic necessity due to the increased copper price.

Guys, rejoice that there are still traditional tin-plated pans with a wall thickness of 3 mm and more!

https://www.toepfeboutique.de/produkt-ategorie/mauviel-1830/mauviel-m200-ci/

Amazingly, the French website hasn’t been updated yet.

Martin, thank you so much for spotting this. It’s worth a post — I am working it up now. I appreciate your sharp eye!

VFC, an interesting development indeed that should be worth a post. Thanks in advance.

The link to the website of a German dealer was unfortunately incorrect. New try:

https://www.toepfeboutique.de/produkt-kategorie/mauviel-1830/mauviel-m200-ci/

Here is the American side of Mauviel with the new offer. However, without any indication that the M’250 series should be replaced. The message is probably brand new.

https://mauviel-usa.com/search?q=M%27200CI

Mauviel will replace M’250B with M’200B from June 2021 too!

https://www.toepfeboutique.de/produkt-kategorie/mauviel-1830/mauviel-m-heritage-m200b-kupfer-und-edelstahl-bronzegriffe/

So far no corresponding information on the American site.

What do you mean by collectibility? The 250b 5-piece set is on sale at cutlery and more and I’m considering buying it. I did the math and while it’s a great deal compared to open stock, I don’t really need the 1.2qt sauce pan, or 10.2″ fry pan (unless you think it’s way better than cooking with All Clad D3 stainless), so I was thinking of getting the M200B 2.1qt saucier….

Hey Angela! Good question. For me, collectibility comes down to a combination of subjective and objective factors: size and thickness; quality and condition; and provenance and rarity. In my opinion, M’250 will always be more desirable than M’200 (and M’150) because the 250 is thicker copper. I’m not qualified to compare M’250 to All Clad as I’ve never used D3, but for what it’s worth I’ve given some 2.5mm fry pans as gifts to those who have used stainless multi-ply and they strongly prefer the copper. (Of course they could just rave about it to make me feel good!)

You’ve given me the idea to write a page about this in more detail. I already have a page on quality and condition (https://www.vintagefrenchcopper.com/buyers-guide/buying-and-selling-online/how-i-evaluate-condition-and-quality/) but I think it would be a good exercise for me to define collectibility as well. Thank you for the inspiration!

As requested , info on mauviel style range.

mauviel style pan with stainless lining and old style logo.

The handle is cast iron in the same design as usual but the handle thickness is noticeable thinner.

Beyond my skill set to post a photo on here I’m afraid

Hey Colin! Thank you! I would love to add some photos — I will send you an email.

Thank you so much for this article! I have a copper Williams Sonoma France branded roasting pan. It appears to missing it’s lid :(. I think it’s Mauviel but I don’t see any branding. Do you know – Is this possible? I believe the handles are cast iron. (I’m new to this, so hopefully that’s right!) I can share a photo thank you!

Hey Kay! The Contact Me page has a way to email me photos. I’d be happy to take a look!

There is one retailer that lists a Cuprinox Style pan in stock in 2022. Take a look at the handle here: https://www.buycoppercookware.com/mauviel-saute-pan-lid-8-last-one-available.html

This looks to be the M’HERITAGE 150s handle, although I have not handled them in person.

I recently purchased a Mauviel 20cm saucepan (M’200 CI) and noticed that the stainless layer on the new pan is substantially thicker than the older models (it looks to me slightly over 0.5mm in thickness), here’s a comparison photo that I took, pan on the left is my old 24cm M’250b Saute pan purchased 2 years ago, the one on the right is the new saucepan, I put them side by side and you can clearly see the thickness difference on the stainless layers.

https://imgur.com/5OEd1Ze

https://imgur.com/Ipcbq7a

Now I’m not sure if the “thicker” stainless layer is a new upgrade from Mauviel this year and I don’t know if it is a improvement. But as long as it doesn’t affect the heating performance of the pan I’m happy with it, at least I don’t have to worry about the stainless being worn out after years of regular use. I’ve read that stainless doesn’t bond to copper very easily, if the layer is too thin, without proper care it can lead to delamination over long period of time, maybe they introduced the thicker stainless layer in hope to make a more stable structure for the pan? what are your thoughts on this?

Hey Kevin — Thank you for this interesting observation. It appears that Mauviel has reformulated (so to speak) the copper sheet for its M’200 pieces. I don’t feel qualified to speak with precision to the difference in cooking performance between the 250b (90-10 copper to steel, according to Mauviel) and the 200 (apparently 75-25 copper to steel) — you are in the best position to compare them! Perhaps you can try some comparison cooking with them and report back?

We have many Mauviel copper pots and pans that we’re going to sell but had no idea how to describe them until I came across your website. I learned a lot and based on your information and guidance, I have determined that the pots were made between 1985-2000 with Cupretram and cast iron handles and not made for any particular retail store. Thank you!!

Wow, really interesting and informative. I’ve been a recent convert and copper cookware enthusiast, having recently acquired a set of four Mauviel saucepans and stockpot. According to the lovely lady I bought them from; she purchased them originally in 1985 from a friend who ran a kitchen store. The store had imported a range of Mauviel cookware to test the market. She used these until her children left home and they became too heavy for day-to-day use, and kept them for display in her own kitchen until she said they would be better off going to someone (like me!) who would appreciate them and use them.

They are nickel lined and approx 3mm thick, which explains their weight. They also came with those ‘lollipop’ lids which she said were great as they’re balanced to let you keep the lid slightly ajar when you need to simmer. A couple of the pans a stamped with ‘Made in France’ and this matches the stamps for Mauviel you’ve described.

So this set is likely from the cuponil line of nickel lined saucepans mentioned in your article and the year of original purchase of 1985 aligns with this.

I did use some copper polish on them (Brasso) to give them that beautiful copper shine, and apart from a good clean that was it. The nickel lining is in excellent condition too. I love using them and they’re beautiful to look at. Unfortunately I don’t have a kitchen where I can leave them out on display!

I’m constantly on the hunt for pieces to add to my collection, but vintage copper is expensive here in Australia, let alone the cost to post from EU/US! (Although I did find a Mauviel gratin pan for sale via Etsy for AU$140 all up inlcu postage from France, which was quite reasonable that I am looking forward to receiving.) I’ll just have to satisfy my fantasies via your website and contributions from your readers!

Interesting enough I never see 250c or 250b in the used market. I would have thought that lots of those were made and that you would see some. I supposed people are holding on to those. As of Aug 2022 you can still get a 10” or 12” 250b frying pan new stock and a couple of the smallest saucepans. That is about it. I wonder how much longer they will be making the tin-lined versions.

Hello again! I have a lovely set of M250C three rivet pans, but the handles are going rusty. What is the best thing to restore them without painting them?

VFC,

thank you for such a great definitive writeup for Mauviel.

Can you expand more on the nickel plated line. I have see your separate post on how to tell nickel from stainless https://www.vintagefrenchcopper.com/2019/02/nickel-versus-stainless-steel/

I would like to know more about the pros and cons with tin vs nickel vs ss. Are they more collectable?

I have a Mauviel 2.5mm copper saute pan that is nickel plated and am just wondering should I stop using it.

thanks

J

VFC,

i just noticed you have more articles on nickel https://www.vintagefrenchcopper.com/2019/09/nickel-the-perfect-metal/. I stand corrected.

If anyone is interested, I am selling a rare find, a large roasting pan from 1940 to 1962 postwar period. The stamp says “Mauviel Villedieu” with the initials “A.M.” inside an oval cartouche, for Armand Mauviel. Without the “Made in France” stamp that came into use in the 1970s. This piece is also stamped “WL 0,” for Wagons-Lits.

https://www.instagram.com/p/Bhjqesdj0HV/?igshid=MzRlODBiNWFlZA==