Copper was often stamped with words or numbers that can be important factors in its value.

In my opinion, stamps don’t change the inherent qualities of a piece of copper — it is what it is, regardless of its markings — but certain stamps can influence the perceived collectibility of a piece, and by extension, its sales price. If you are interested in buying or selling copper, I think it is well worth your time to become familiar with the meaning behind the stampings on the pieces you encounter.

Quick search

If the stamp has full words in it — a name or a street address — use the search box in the sidebar at right to see if it’s a maker or store that’s been written about on this site.

Stamps with a name and location

A multi-element stamp — that is, one with multiple words in it — is most likely a professional marking applied when the piece was made. The copper makers sold copper directly to customers but also through retail kitchenware stores. This means that certain pieces of copper were given a maker’s mark, while others were given the stamp of the store that sold it.

Here are some examples of maker’s marks. There are many more.

And here are some examples of store marks.

It can be hard to tell a maker’s mark from a store mark until you become familiar with the common makers and retailers. I’ve gathered together what I’ve learned here:

- Field guides for the more well-known makers

- An index of store stamps in Europe and the United States

- A list of the smaller makers and shops in Villedieu

- Three major 19th century department stores in Paris that carried custom-designed copper

Stamps with just a name or initials

Stamps with one or two words are most likely an owner’s mark. Antique and vintage tinned copper was fairly frequently stamped for its owner to keep track of it while it was being retinned or repaired, to help deter theft, and possibly just for pride. In my experience, the practice of applying owner’s marks seems to have declined after WWII.

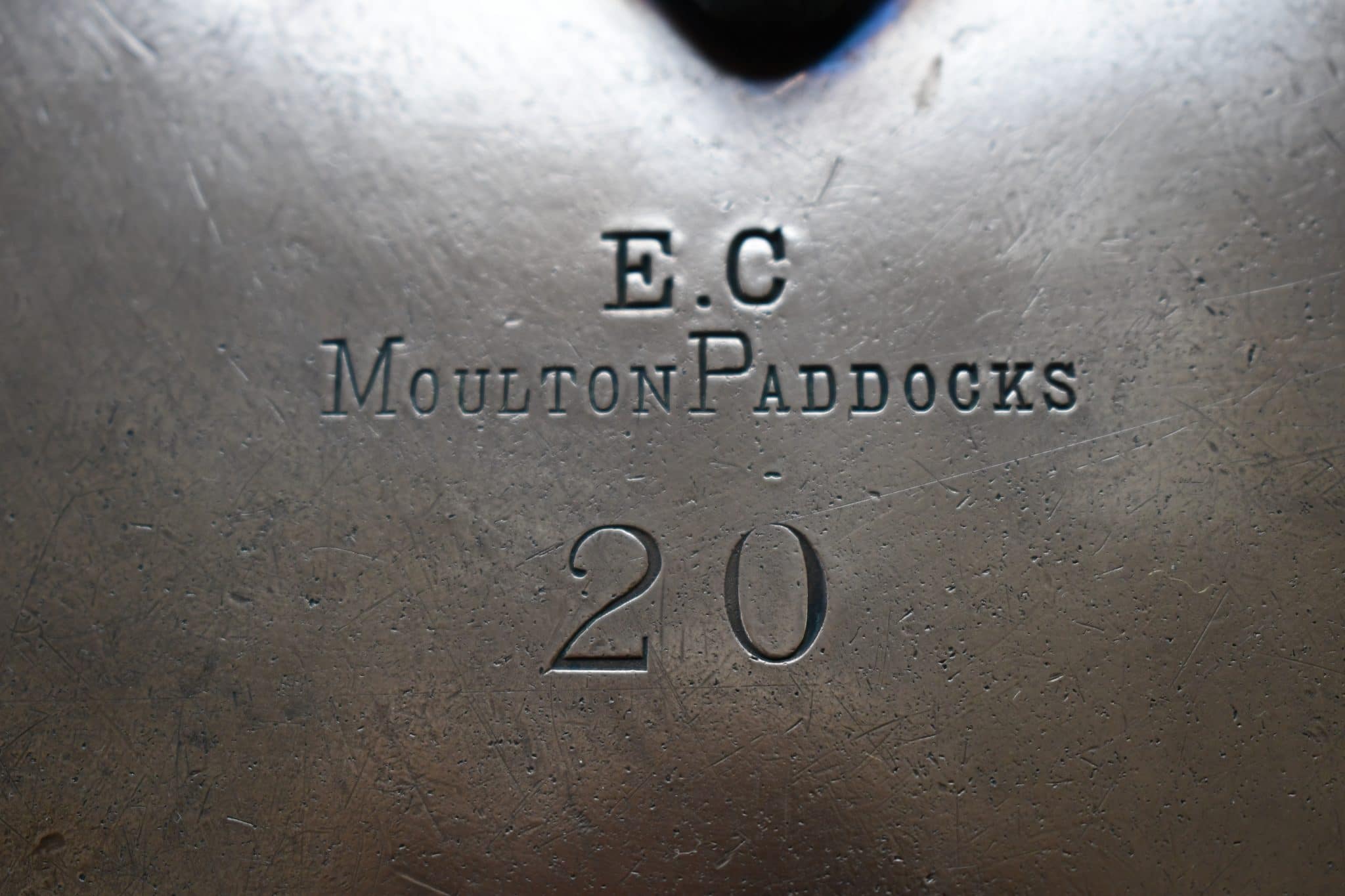

Full or partial words could refer to a restaurant or hotel; a royal residence or country estate; the property of a railway company that cooked meals in their restaurant cars; or simply an owner who wished to have his or her copper clearly labeled.

Here are some examples of owner’s marks that I have been able to research.

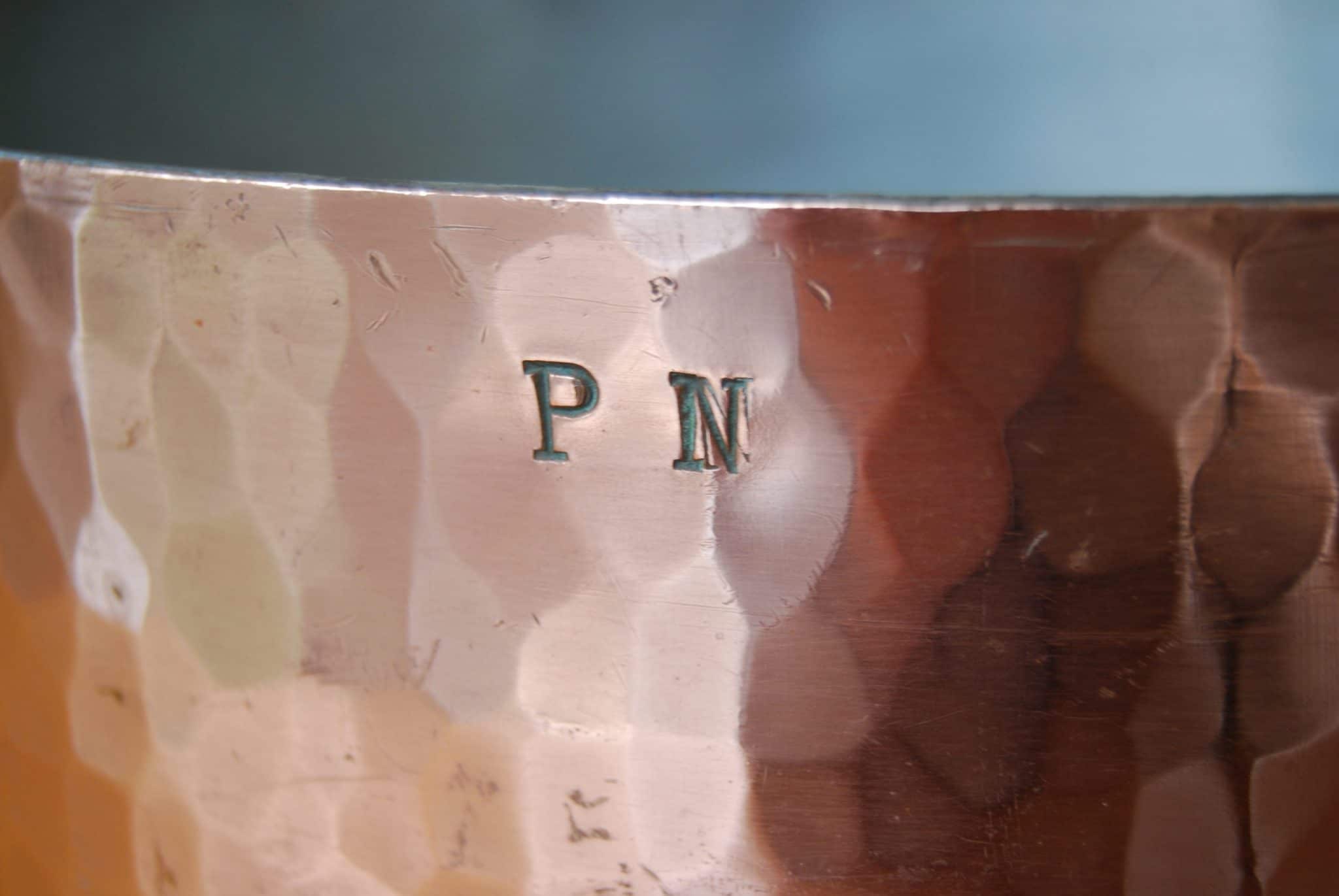

Initials are more challenging to research without additional context to narrow the possibilities. But in my opinion an owner’s stamp confers some charisma onto a piece — after all, someone cared enough for it to claim it!

Here are some examples of stamps that are just the owner’s initials.

“Made in France”

In the 1960s or so, copper cookware produced in France began to carry a “Made in France” stamp on it. My understanding at the moment was that this was a legal requirement imposed by the European Economic Community (the precursor to the European Union), which was formed in 1957. My study of the craftsmanship of copper with this stamp aligns with that time period.

This marking is useful to the identification process in two ways:

- The piece of copper was made and sold after 1957 (again, assuming I am correct about the timing); and

- Because each copper maker had its own version of the stamp, and you may be able to identify the piece this way.

If you have a piece of copper with nothing but “Made in France” on it, please take a look at my Made in France article for my efforts to link this stamp to specific makers.

Numbers

A two-digit number is usually the diameter of the pan in centimeters, while a one-digit number is usually a reference number to match the pan to its lid, and perhaps also to its spot on the shelf of a busy kitchen. I’ve taken a stab at connecting the typefaces of number stamps with known makers.

Here are some examples of number stamps. The double-digit ones are usually sizes in centimeters — the length of a daubiere or diameter of a stockpot — while single-digit numbers are more likely identification numbers.

No stamps at all?

Don’t give up yet — you can look at a pan’s construction to get an idea of when it was made, and in some cases, get some clues to its maker.

And again, to restate the point: Stamps may make a piece more collectible (and therefore more valuable), but they don’t necessarily make it better. In my opinion, copper quality comes down to its level of craftsmanship, the thickness of the sheet metal, and its physical condition.